In the heartlands of the USA, of all places, a social (some spoke of a socialist) experiment in the steel industry took place in 1984.

The workers of the Weirton steelworks in West Virginia took over 100 % of their mill from the National Steel Comp. .

It now was the only integrated steel mill in the western hemisphere that was employee owned.

The Employee Stock Option Plan (ESOP) was ment to save 8000 jobs in Weirton.

Although the mill initially became profitable again, the plan failed in the end.

In 2003 Weirton Steel went bankrupt and was sold to ISG for only $237 million in 2004.

With the exception of one cold rolling mill, owned by ArcelorMittal, the plant has been shut down and is currently being demolished.

I visited the site in 2004 and was allowed to take this hard hat with me as a reminder of the good old socialist times.

Tag Archives: USA

8/72. Bethlehem Steel, Lackawanna

Image shows the Bethlehem Steel Mill in Lackawanna, NY south of Buffalo at the Lake Erie shoreline probably in the late 1960ies.

Foreground shows the 535 coke ovens along the dock, behind are the seven blast furnaces and (right hand side) the open hearth melt shop (35 furnaces).

The background is also attractive:

Right from the centre we can see National Steel’s Hanna Furnaces and far away in the middle Republic Steel’s Buffalo works.

Lackawanna was closed down in 1983.

- BF A: Ø 21’3” (6,47 m)

- BF B: Ø 21’3” (6,47 m)

- BF C: Ø 28’0” (8,53 m)

- BF F: Ø 26’0” (7,92 m)

- BF G: Ø 27’0” (8,22 m)

- BF H: Ø 29’0” (8,83 m)

- BF J: Ø 29’11” (9,11 m)

7/72. United States Steel Corp., Gary Works.

Although I generally prefer old style intraurban steel mill sites to modern greenfield facilities Gary, Indiana in the 1960ies must have been the place to be for a steel mill photographer.

Here is the data sheet (1965):

Coke Plant:

497 Koppers ovens

385 Wilputte ovens

Sintering Plant:

5 Strands

Blast Furnaces:

No.1 Ø 6.24 m

No.2 Ø 6.24 m

No.3 Ø 6.24 m

No.4 Ø 8.61 m

No.5 Ø 6.24 m

No.6 Ø 8.53 m

No.7 Ø 8.53 m

No.8 Ø 8.07 m

No.9 Ø 7.01 m

No.10 Ø 8.22 m

No.11 Ø 7.62 m

No.12 Ø 7.62 m

Open Hearth Steel Plants:

24 x 150 t furnaces

14 x 167 t furnaces

6 x 184 t furnaces

4 x 190 t furnaces

2 x 300 t furnaces

Bessemer Plant:

3x 25 t converters

Rolling Mills:

3 x Blooming/Slabbing

1x Billet

1x Rail

1 x Plate

9 x Bar

2 x Strip

Forge:

6x Steam hammers

3 Presses, 1000 t, 2000 t, 10000 t

Forging

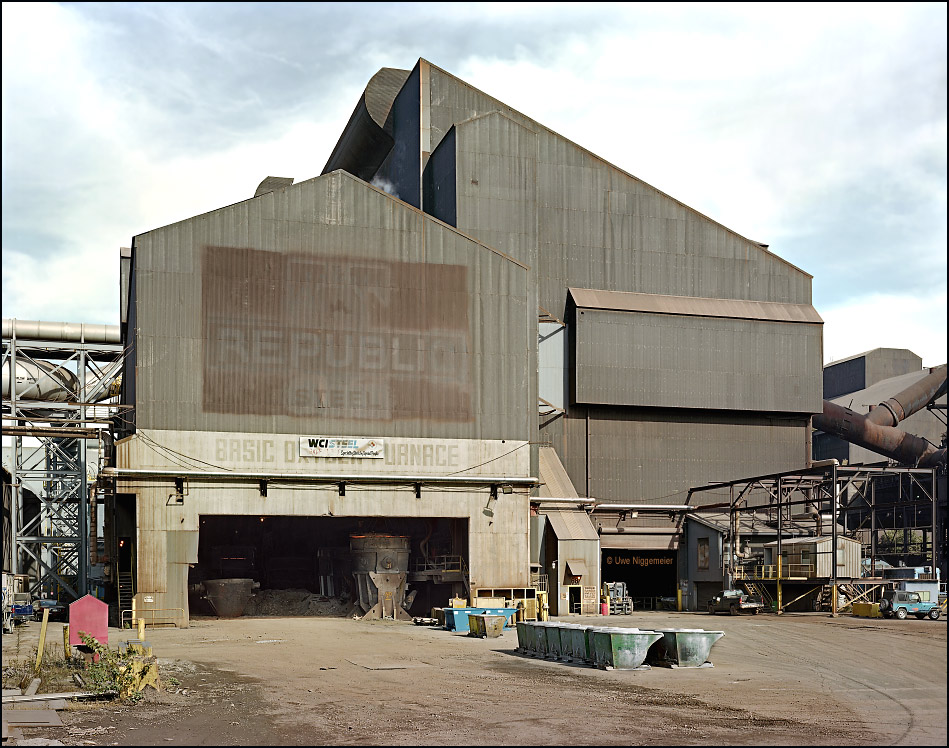

Weirton BOF Shop Demolished

The former National Steel BOF shop was demolished last week.

The basic oxygen steel making shop with it’s 330 t vessels

operated from 1967 to 2005.

I visited it in 2004.

Abandoned Bars

Replaced By An EAF

The Republic Steel company just fired up it’s new electric arc furnace in Loraine, Ohio. It replaces two blast furnaces and a BOF steel making shop idled five years ago.

Blast furnace No. 3 has a hearth diameter of 8,68 meters, furnace No 4 is 8,83 meters wide.

The BOF shop was built in 1971 and it contains two 220 ton vessels.

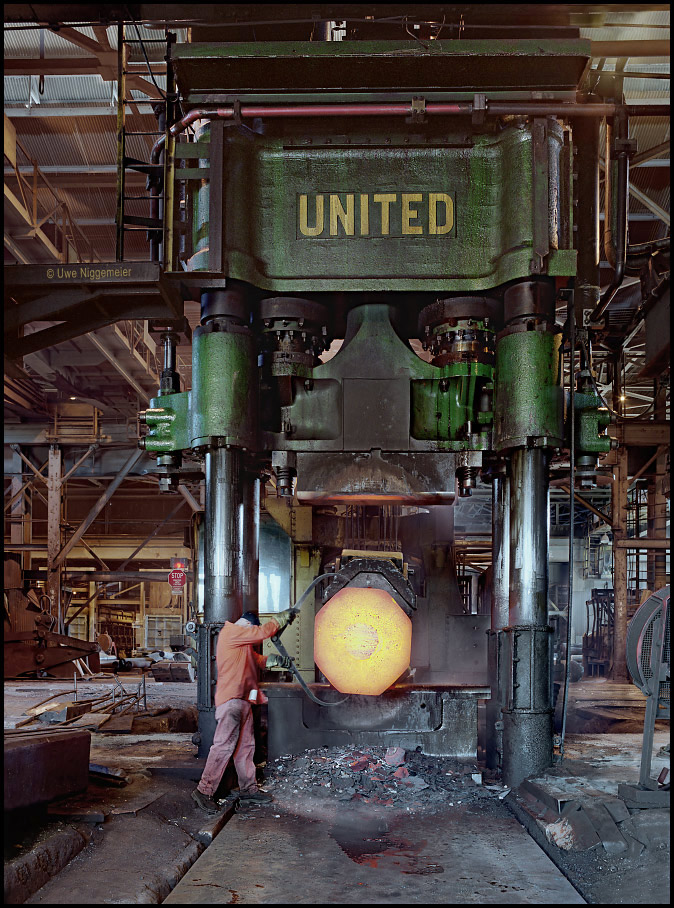

Rolling Mill Operators

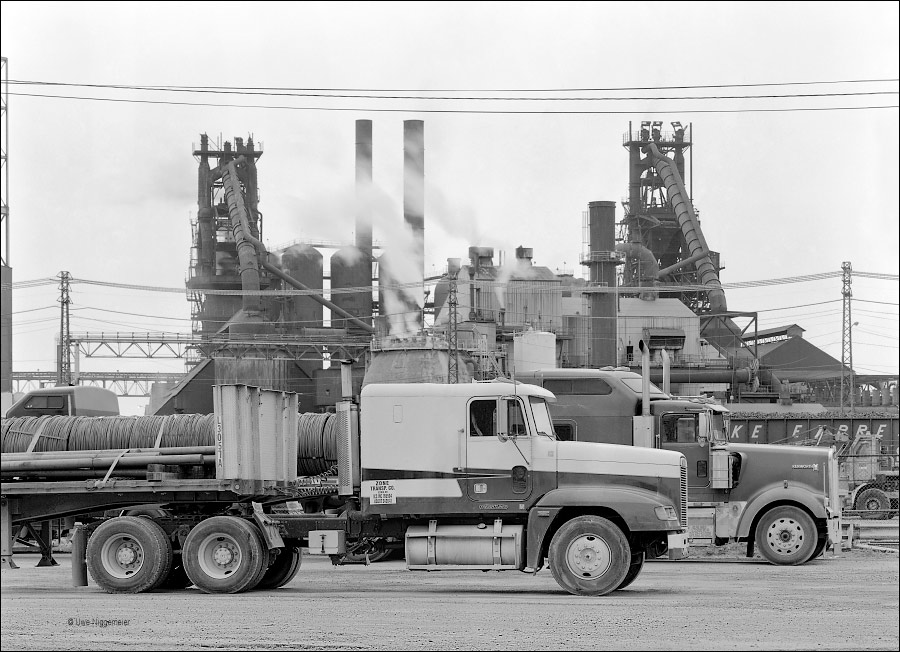

Demolition Started

Demolition started at the former RG Steel plant in Warren,OH that was purchased by the Hilco company in May. This deal required to market the hot mill for three months before beginning to raze the plant. Those three months expired at the end of August.

Founded in 1912 as the Trumbull Steel Co., the mill has a long history in steel production. In 1928, the company merged with Republic Iron and Steel Co. and, two years later, was renamed Republic Steel Corp. Another merger changed its name to LTV Steel Co. when it combined with J&L Steel Corp. in 1984. The company became Warren Consolidated Industries, Inc. in 1988.

WCI Steel employed 2,600 people, and had an annual steel capacity of 1.5 million tons. In 2008 WCI was taken over by the Russian steel company Severstal.

Three years later Severstal sold the plant to RG Steel who filed bancruptcy in 2012.

The Warren Blast Furnace once was the largest worldwide.

A few images from 2007.