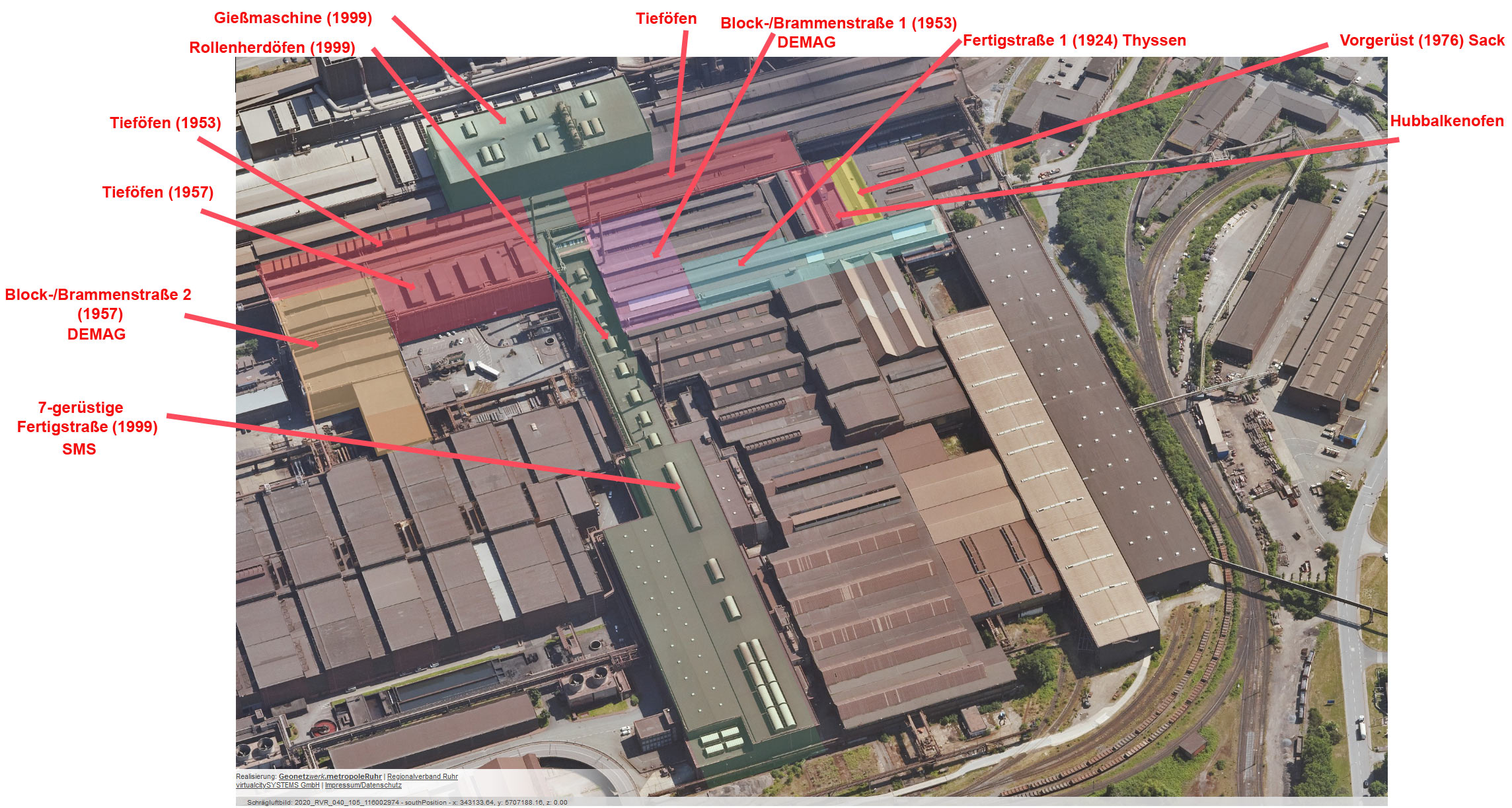

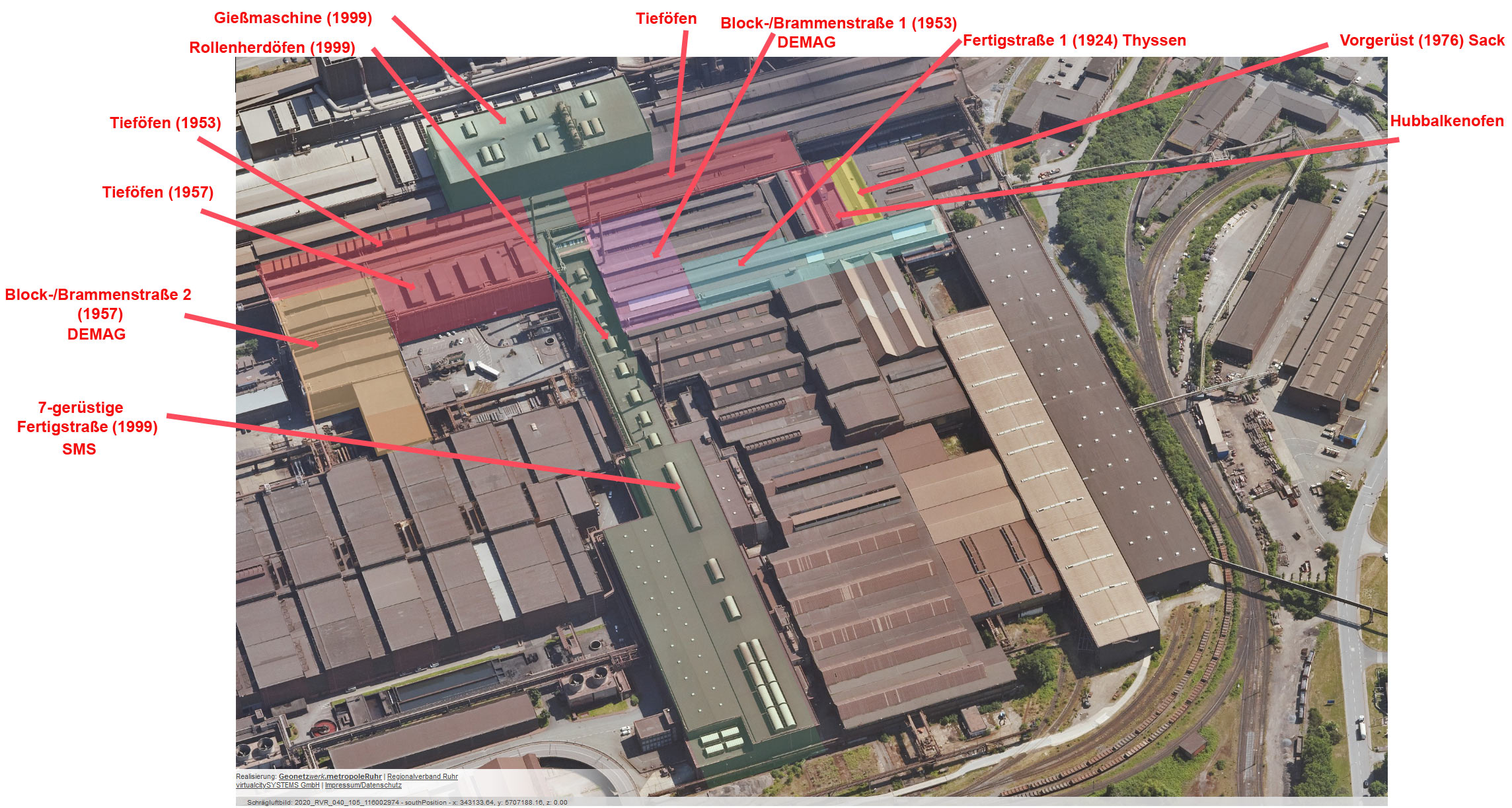

Da es bei thyssenkrupp Steel nordwestlich des Oxygenstahlwerks in Bruckhausen z.Z. zu nicht unerheblichen Abrissarbeiten kommt hier mal eine grobe Übersicht über die ehem. dort vorhandenen Anlagen.

© RVR, 2020, dl-de/by-2-0

Da es bei thyssenkrupp Steel nordwestlich des Oxygenstahlwerks in Bruckhausen z.Z. zu nicht unerheblichen Abrissarbeiten kommt hier mal eine grobe Übersicht über die ehem. dort vorhandenen Anlagen.

© RVR, 2020, dl-de/by-2-0

Mit der gestrigen Mittagsschicht hat thyssenkrupp Steel die Produktion von Grobblechen eingestellt.

Das Grobblechwalzwerk in Duisburg-Hüttenheim wurde 1963 durch die Mannesmann AG zur Versorgung des benachbarten Großrohrwerks (Stilllegung 1978) mit Blechen erbaut.

1970 übernahm die August Thyssen Hütte im Tausch mit ihren Rohrwerken die Flachstahlsparte von Mannesmann. 1978 wurde das neue 3,9 Meter Quartogerüst durch die Sack Maschinenbau GmbH installiert.

Anläßlich ihres 20-jährigen Jubiläums wurde die GWA noch als weitsichtige und lohnende Investition bezeichnet, nun aber, nur ein Jahr später, wird sie stillgelegt.

Anläßlich ihres 20-jährigen Jubiläums wurde die GWA noch als weitsichtige und lohnende Investition bezeichnet, nun aber, nur ein Jahr später, wird sie stillgelegt.

Als die GWA im April 1999 in Betrieb genommen wurde war sie die erste Anlage ihrer Art in einem integrierten Hüttenwerk weltweit.

Offenbar hat sich die Erzeugung von Breitband in einer Hitze in diesem Rahmen aber nicht bewährt denn Thyssen-Krupp Steel kündigt an die Anlage zu einer Warmbreitbandstrasse klassischer Bauart umzubauen.

revisited.

The Rothe Erde GmbH was founded in 1855 in Dortmund under the name Paulinenhütte. Main product was railroad equipment.In 1861 the Rothe Erde steel company from Aachen purchased the mill an gave it it’s final name. From 1926 on Rothe Erde was part of the Vereinigte Stahlwerke, the second largest steel producer worldwide. After rebuilding the destroyed works in the 1950ies Rothe Erde became part of the Hoesch steel group in 1966 and started to built up a modern ring rolling mill at their Dortmund works.

After the takeover of Hoesch by the Fried.Krupp steel company in 1993 Rothe Erde finally became part of the ThyssenKrupp group in 1999.Nowadays the Dortmund works are one of the largest ring rolling mills in Europe producing rings up to 8 meters.Further processing of rings to bearings or turntables is done in Dortmund and Lippstadt.

A history of more than 170 years of steel making ended in Bochum, Germany in late June when the Nirosta stainless steel plant was closed for good.

The original BOF shop was built in 1957 by the Bochumer Verein to be only the second of it’s kind in Germany.

In 1972, after the closure of the blast furnace site both vessels were transformed into AOD converters and an electric arc furnace was installed in the same building to produce stainless steel.

In 1982 a huge new 135 MVA electric arc melt shop was attached and the old EAF was replaced by a ladle furnace.

I payed the site a final visit before the demolition started.

installed motor capacity makes the ThyssenKrupp hot strip mill in Bochum the most powerful rolling mill in Germany. Though the mill was already planned in the early 1960ies by the Bochumer Verein steel corporation it wasn’t until 1966, after the takeover by the Fried. Krupp company, that the mill was put into operation.

The mill is capable of rolling even high alloyed speciality steel.

After the closure of the adjacent Nirosta steel mill all primary material now comes from the August Thyssen Hütte in Duisburg.

Images now at stahlseite.

The unique casting rolling unit at ThyssenKrupp’s integrated steel mill in Duisburg, Germany produces strip up to 1,6 m wide with a combined caster and a 7-stand finishing mill in one heat.

The facilities were installed in 1999.

Images now at Stahlseite.

The new coking plant Schwelgern in Duisburg, Germany was commmissioned by ThyssenKrupp in 2003 replacing the old August-Thyssen coke ovens.

Two batteries of 70 ovens each were built.

Some images now at Stahlseite.