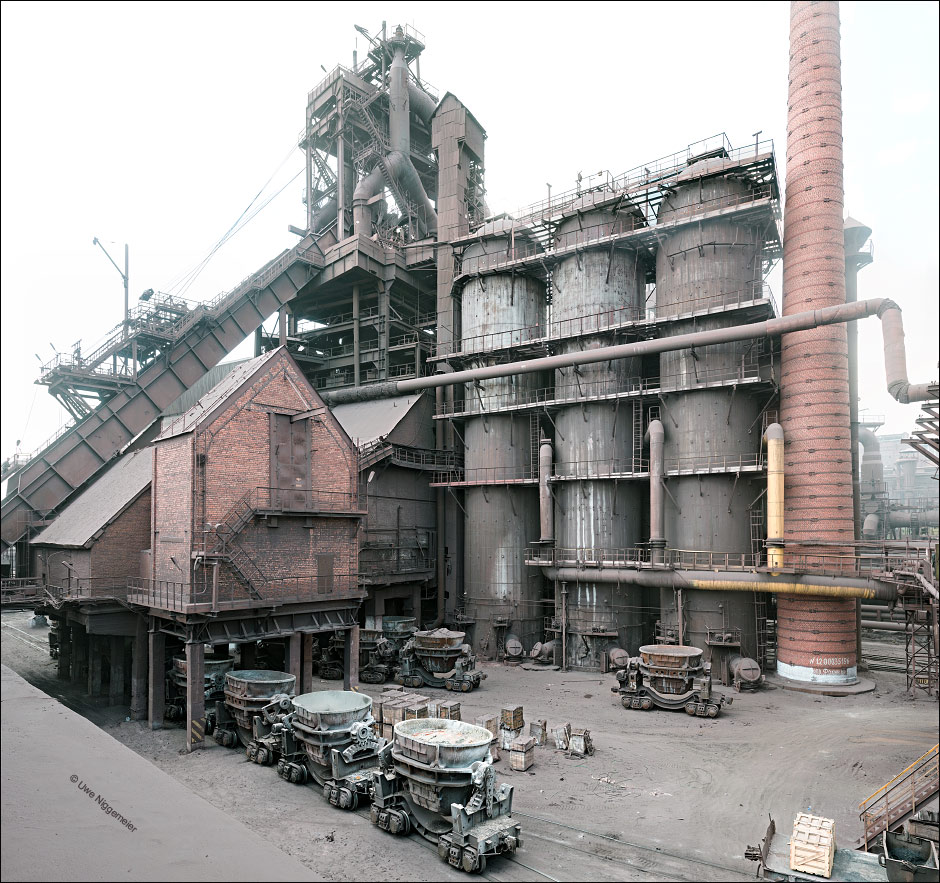

Ural Steel. Novotroitsk, Russia.

The Ural region is a cradle of the Russian iron and steel industry.

Based on it’s rich iron ore deposits a vast number of charcoal fired blast furnace sites emerged in the 18th century. Most of these are gone today, replaced by the huge combines of the communist era. A few have survived, mostly rusting away in the harsh climate of the eastern Ural:

The Verhnesinyachihinsky Metallurgical Plant in Werchnjaja Sinjatschicha was founded 1769 and went bancrupt in 2012.

The Alapaevsk Iron Works origin from 1704 and seem to be idled by now.

The Kuibyshev Metallurgical Plant in Nizhny Tagil goes back to the Demidov iron company from 1725 and was closed in 1987. It hosts a museum but seems to be in a rather poor condition and seldom opened to the public.

Images at Stahlseite.de .

Deep down in southern Russia, close to the Kazakh border, the Ural Steel mill in Novotroitsk was founded in 1955 under the name Orsko-Khalilovsky Iron-and-Steel Works.

In the same year blast furnace no. 1 went into production.

The first steel was produced at open-hearth furnace no.1 in 1958.

In 1960 the 2800-mm plate rolling mill no.1 was installed.

A section rolling mill was put into operation in 1969.

In 1978 a 800-mm wide strip universal rolling mill was commissioned .

The EAF Shop was built in 1981.

1983 – The first continuous casting machine was put into operation at the EAF shop.

Today Ural Steel runs a coking plant,four blast furnaces, two electric arc furnaces (100 ton each) and four rolling mills.

Further images at Stahlseite.

I ever visited is located in the southern Ural, Russia.

The 250m³ (9000 cu-foot) furnace produces ferromanganese casted in pig beds.

The Satka Iron Smelting Works is the oldest existing iron producer in the Ural and among the first to be built in Russia.

Settled on the banks of the Bolshaya Satka river the mill went into production in 1758 founded by Baron Stroganov.

Two blast furnaces and 12 hammers were in operation.

In the 1860ies a puddling steel mill was added.

Since 1910 ferro alloys were produced.

In the 1930ies more than 1300 people worked in the mill, cast iron became the major product.

After financial troubles the plant became partly idled in the 1990ies until the Ivanov family coming from the Swerdlowsk region took over in 2001 annd decided to switch production to high carbon ferromanganese an alloying element for the steel industry.

Satka Iron Smelting Works today runs two blast furnaces of 250m³ and 350m³.

Further images at Stahlseite.