The famous German industrial architect built this melt shop in 1957 for Phoenix Rheinrohr in Duisburg, one of the largest German steel companies of that time. It was equipped with three Thomas converters and one modern oxygen converter.

The building underwent several changes over the years especially when it was transformed into a BOF shop in 1969.

Nowadays the ArcelorMittal Ruhrort plant runs a steel making shop with two 140 ton BOF vessels (and one in reserve), two continuous casters and a two stand billet mill. Hot metal comes from the ThyssenKrupp steel company in Duisburg via bottle cars.

Further images on my site.

Tag Archives: ArcelorMittal

Huta Krolewska

The Huta Kroleweska in Chorzow, Poland was founded in 1797 and started the production of pig iron in 1802. It was named “Königshütte” in honour of the Prussian King.

In 1843 a puddling steel mill and the first rail mill went into production.

Until 1860 four blast furnaces and a coke plant were built.

In 1872 the German painter Adolph Menzel visited the works to create his famous painting “Eisenwalzwerk (moderne Cyclopen)”

An open hearth melt shop was installed in 1880 and a Bessemer plant was added in 1895. By 1909 the Puddling and Bessemer mills were closed and in 1912 a Thomas converter melt shop was comissioned.

Under Polish administration the plant was renamed “Huta Pilsudski” in 1935. During the German occupation the mill was called Königshütte again and after the war the name of “Huta Kosciuszko” was used.

In 1949 the DEMAG medium and light sections rolling mill was installed.

In the 1950ies new blast furnaces and coke oven batteries were built.

More than 8000 people were employed.

Steel production ceased in 1978, the coke plant was closed in 1982 and the last blast furnace was blown out in 1991. In 1992 the wire rolling mill was closed down.

In 1994 a new walking beam furnace was installed for the heavy sections rolling mill.

In 1997 the light and medium sections mill was modernized.

The Huta Kosciuszko became a shareholders company in 1998.

In 2007 the ArcelorMittal steel company takes over the mill under the name “Huta Krolewska” (Germ., Königshütte).

Huta Krolewska today runs a heavy sections rolling mill mostly for rails and a light and medium sections mill.

Raw materials are provided by the Huta Katowice in Dabrowa Gornica.

Further images at stahlseite.de.

Video done by a french film maker in the 1980ies.

The End Of Another Steel Valley

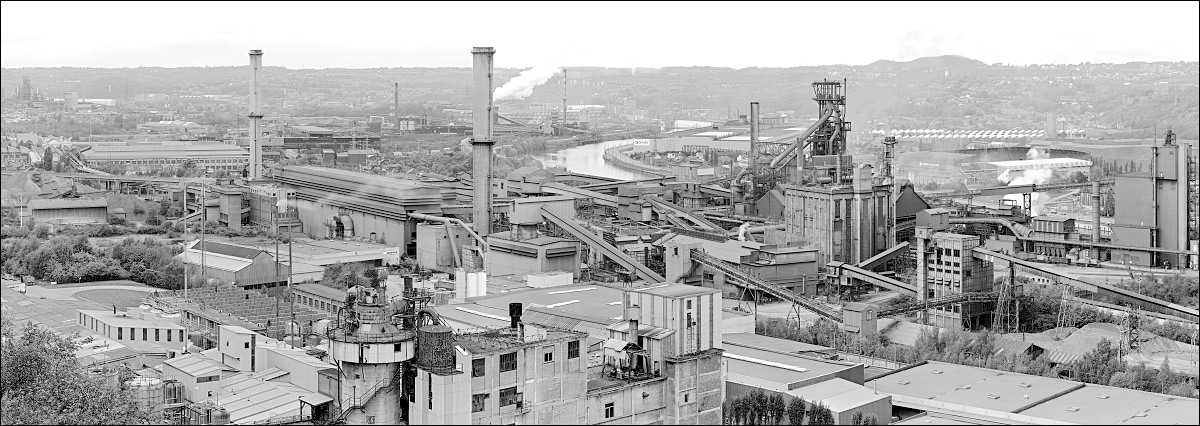

Today the ArcelorMittal steel company announced the closure of the majority of it’s remaining steel production sites in the Meuse valley near Liege, Belgium.

About 1300 of the remaining 2100 steel workers in the valley will loose their jobs.

Apart from the hot strip mill and the coking plant a cold rolling mill and two galvanisation lines will be closed for good.

The liquid phase steel production was already closed in October 2011.

The Meuse valley around Liege is one of the cradles of the European industrialisation.

Huta Katowice

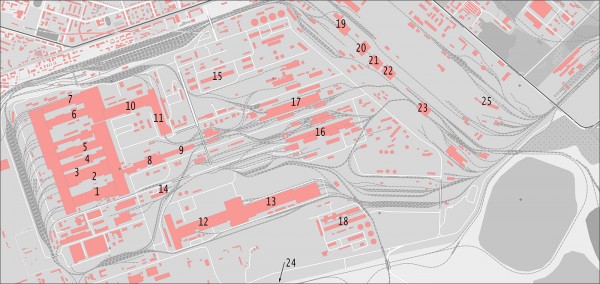

The steel mill in Dabrowa Gornica, Poland was built in between 1972 and 1976. It was named “Huta Katowice” after the nearby industrial town.

Three blast furnaces were built in between 1976 and 1987 (hearth diameter 12,00 m).

The mill was taken over by the Mittal Steel Corp. in 2003 and got it’s new name ArcelorMittal Dabrowa Gornica in 2007.

Besides the three blast furnaces (No. 1 is permanently idleld) the mill operates a BOF shop containing three BOF vessels, two continuous casters (one for billets and one for slabs) and two rolling mills (Heavy and medium sections).

Dabrowa Gornica provides primary material for all ArcelorMittal sites in Poland.

The attached coke plant was sold to an external company.

Further images at stahlseite.de .

1: Blast furnace No. 1

2: Blast furnace No. 2

3: Blast furnace No. 3

4: BOF shop

5: Continuous caster

6: Heavy sections rolling mill

7: Medium sections rolling mill

8: Power plant

700 Ton Open Hearth Furnace

The steel mill in Kryvyi Rih (Russ. Krivoy Rog) was founded in 1931 on the rich iron or deposits of the Ukrainian Kryvbas basin.

In 1934 the mill was ready to produce hot metal out of one blast furnace. By 1939 three blast furnaces a coke plant and a Bessemer shop were in operation. In the second world war the Kryvyi Rih Metallurgical Works were dismantled by the Soviets and the remains destroyed by the German army.

In 1949 blast furnace No.1 was blown on. By 1960 four rolling mills and a 600 ton open hearth furnace were installed.

Blast furnace No.7 was built in 1962, No. 8 and No. 9 (one of the largest worldwide) followed in 1970 and 1974.

In 1996 the Kryvyi Rih State Mining and Metallurgical Combine (Krivorizhstal) brought together the metallurgical and the mining activities in the Kryvbas basin.

In 2004 the mill was privatized for the first time to an Ukrainian syndicate.

This was canceled one year later and the second privatisation found the Mittal Steel company as a new owner.

Since 2007 Krivorizhstal is part of the worlds largest steel company ArcelorMittal.

Today ArcelorMittal Kryvyi Rih employs 35000 people main products are billets, bars, rod and wire.

Further viewing.

1: Light-section mill 250-2

2: Rod mill 150-1

3: Light-section mill 250-1

4: Light-section mill 250-3

5: Light-section mill 250-4

6: Light-section mill 250-5

7: Rod mill 250-3

8: Blooming mill No.1

9: Soaking pits

10: Blooming mill No.2

11: Soaking Pits

12. Light-section mill 250-6

13: Wire mill

14: Forge shop

15: Oxygen plant

16: BOF shop (6×160 ton)

17: Open hearth shop (1×550 ton, 1×700 ton)

18: Power station

19: Blast furnace No.8

20: Blast furnace No.7

21: Blast furnace No.6

22: Blast furnace No.5

23: Blast furnace No.1

24: Blast furnace No.9

25: Coke plant (6 batteries)

Vintage coke ovens dismantled

During today’s visit at ArcelorMittal’s Zdzieszowice coke plant in Poland I could convince myself that Europe’s probably oldest existing coke oven batteries are completly dismantled by now.

The batteries NO 1 & 2 were built by Gräflich Schaffgotsche Werke in 1932 and 1938.

The location 50 kilometers away from the next coal mine and without any steel industry in the vicinity was chosen mostly for political reasons. The administration had decided to offer industrial jobs for the German population in this rural part of Silesia.

The design for this new coking plant was done by Fritz Schupp and Martin Kremmer from Germany. Both batteries had a stamp charging system and were built by the Still company. The batteries were shut down in 2008 and dismantled in 2010.

ArcelorMittal Zdzieszowice today runs 8 oven batteries (3-6 are stamp charged and 7,8,11 and 12 are top charged) of which 4 were rebuilt in the last 10 years. Batteries NO 9 and 10 were dismantled recently too.

Zdzieszowice is the largest coke plant in Europe producing more than 4 mio. tons of metallurgical and domestic coke each year.

Steelton rail rolling mill

The Steelton plant was founded in 1867 by the Pennsylvania Steel Corp.. It was the first mill in the U.S. built exclusivly for the production of steel.Main product were steel rails already.

Three blast furnaces and a Bessemer mill were erected along the Susquehanna river in the late 19th century

In 1917 the mill was taken over by Charles Schwab’s Bethlehem Steel Corp.

The blast furnaces were closed for good in 1960.Steel was produced now by remelting scrap in open hearth furnaces only.

The open hearth furnaces were replaced by electric arc furnaces in 1968.A continuous caster was installed in 1983.

In 2001 the Bethlehem Steel Corporation went bankrupt and was taken over by ISG which later became part of ArcelorMittal.

Today ArcelorMittal operates a 150 ton electric arc furnace, a continuous bloom caster, a 44” blooming mill, a 20” bar mill, and the 38-25” rail mill at Steelton. Large scale ingot teeming is still done also.

Steelton is one of only three remaining rail producers in U.S. today.

Burns Harbor: The last integrated steel mill built in the United States.

50 years ago the Bethlehem Steel Company from Pennsylvania started building a new, state of the art, integrated mill on the banks of the Lake Michigan. 3000 acres of land, neighbouring US Steel’s Gary works, were purchased and construction started in late 1962. Probably few could have imagined that Burns Harbor would be the last integrated mill in the U.S. to be built until today.

In 1964 the 160 “ plate mill was started followed in 1966 by the 80” hot strip mill. In between 1969 and 1972 two blast furnaces, a coke plant (164 coke ovens) and a steel mill, containing two 300 ton BOF vessels were started.In 1975 Bethlehem Steel’s first continuous slab caster started production. In 1978 a 110” plate mill and a third BOF vessel became operational.In 2000 the last ingots were poured.

After filing bankruptcy Bethlehem Steel was taken over by the International Steel Group (ISG) in 2003. Two years later Burns Harbor became part of Mittal Steel USA (ArcelorMittal since 2007).

Further images.

1: Blast furnace C

2: Blast Furnace D

3: Ore storage

4: Coal Storage

5: Coke plant

6: Sinter plant

7: BOF shop

8: Slab caster 1

9: Slab caster 2

10: 80″ hot strip mill

11: 160″ plate mill

12: 110″ plate mill

13: Cold rolling mill

Rien ne va plus

According to the French newspaper Liberation AcelorMittal announced to shut down the hot end of it’s last integrated steel mill in Lorraine, France at Florange permanently.

The two remaining blast furnaces P3 and P6 that were idled in 2011 will not be restarted by AM.

ArcelorMittal is said to have offered the iron and steel making facilities at Florange to the French Government for one Euro to find a new owner within the next few month.