After Sparrows Point’s 12 year old cold rolling mill has been sold to the Nucor Steel company for use as spare parts it becomes very unlikely that the rest of the mill will find a new operator. Local officials claim to have information that the current owner will demolish the whole site now.

Teeming Ingots

BGH(Boschgotthardshütte) Freital is a speciality steel mill just outside of Dresden, Germany.

It was founded in 1855 under the name Sächsische Gußstahlfabrik benefited by the local iron ore and coal deposits.

After the second world war it was completly dismantled by the Soviets and rebuilt afterwards now called VEB Edelstahlwerk 8. Mai 1945 (date of the German capitulation).

The mill employed more than 5000 people and used to bet he largest speciality steel producer in the former DDR.

After the German reunification in 1990 the work force succesfully fought for the survival of their steel mill and Freital was privatized by the West German entrepreneur Rüdiger Winterhager from Siegen.

Today BGH Freital produces speciality steel in a 42 ton electric arc furnace and a downstream ladle furnace plus a VOD facility for further steel refining.Casting is done in a continuous horizontal caster or by teeming ingots.

The rolling department includes a blooming mill and a bar and wire rolling mill.

The forging division contains a continuous forging machine and a hammer mill.

BGH Freital employes more than 600 people. Further images at Stahlseite.

Steel Foundry

The Silbitz foundry was established in 1938 in a rather remote area of the German Reich to produce military equipment. During the war more than 1000 workers were employed.

In 1946 the foundry was nationalized and became part of the SAG Marten (Soviet stock company) and in 1954 the VEB Stahlgiesserei Elstertal Silbitz. This company was privatized in 1990 and is named Silbitz Guss GmbH since.

The foundry produces nodular iron and steel castings up to eight tons a piece.

Two eight ton electric arc furnaces and four induction furnaces are in use.

Further images.

Natrona, Pennsylvania

A small, former, industrial village on the banks of the Allegheny River.

In the background the remarkable Allegheny Ludlum melt shop from 1966 that hosts a huge 114″ (2,90 meter) hot blast cupola furnace, two 80 ton BOF vessels and three 70 ton induction furnaces. The cupola furnace produced up to 65 tons of hot metal per hour and was closed down in the late 1970ies to be replaced by the induction furnaces.

The melt shop was shut down in 2010 and is now demolished.

700 Ton Open Hearth Furnace

The steel mill in Kryvyi Rih (Russ. Krivoy Rog) was founded in 1931 on the rich iron or deposits of the Ukrainian Kryvbas basin.

In 1934 the mill was ready to produce hot metal out of one blast furnace. By 1939 three blast furnaces a coke plant and a Bessemer shop were in operation. In the second world war the Kryvyi Rih Metallurgical Works were dismantled by the Soviets and the remains destroyed by the German army.

In 1949 blast furnace No.1 was blown on. By 1960 four rolling mills and a 600 ton open hearth furnace were installed.

Blast furnace No.7 was built in 1962, No. 8 and No. 9 (one of the largest worldwide) followed in 1970 and 1974.

In 1996 the Kryvyi Rih State Mining and Metallurgical Combine (Krivorizhstal) brought together the metallurgical and the mining activities in the Kryvbas basin.

In 2004 the mill was privatized for the first time to an Ukrainian syndicate.

This was canceled one year later and the second privatisation found the Mittal Steel company as a new owner.

Since 2007 Krivorizhstal is part of the worlds largest steel company ArcelorMittal.

Today ArcelorMittal Kryvyi Rih employs 35000 people main products are billets, bars, rod and wire.

Further viewing.

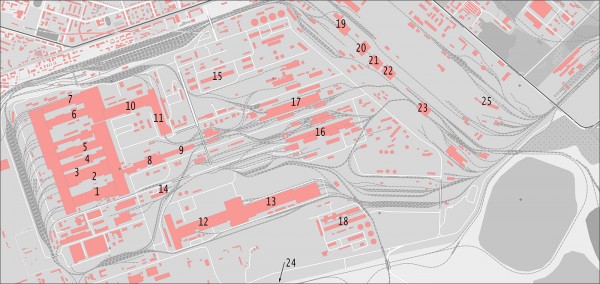

1: Light-section mill 250-2

2: Rod mill 150-1

3: Light-section mill 250-1

4: Light-section mill 250-3

5: Light-section mill 250-4

6: Light-section mill 250-5

7: Rod mill 250-3

8: Blooming mill No.1

9: Soaking pits

10: Blooming mill No.2

11: Soaking Pits

12. Light-section mill 250-6

13: Wire mill

14: Forge shop

15: Oxygen plant

16: BOF shop (6×160 ton)

17: Open hearth shop (1×550 ton, 1×700 ton)

18: Power station

19: Blast furnace No.8

20: Blast furnace No.7

21: Blast furnace No.6

22: Blast furnace No.5

23: Blast furnace No.1

24: Blast furnace No.9

25: Coke plant (6 batteries)

Closed for good

The AFV Beltrame Group from Italy declared on monday that they will shut down their bar rolling mills in Monceau s. Sambre, Belgium and in Esch-Schifflange, Luxembourg definitly.

Images of the Laminoirs Du Ruau and the Train A Lamines Marchands.

Heavy Rolling

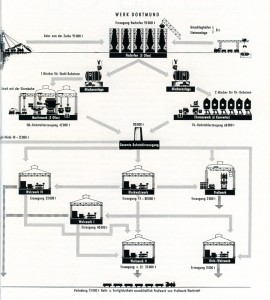

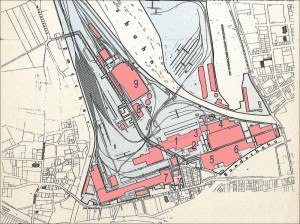

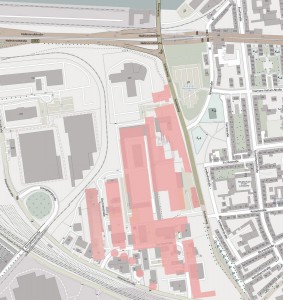

Hoesch Spundwand und Profile (HSP) is the last survivor of the once fully integrated Dortmunder Union steel mill.

The Union AG für Bergbau, Eisen- und Stahl-Industrie was founded in 1872 west of Dortmund in Germany.

In 1881 three blast furnaces were built.

After the Union became part of the Deutsch-Luxemburgische Bergwerks- und Hütten-AG in 1910 an extensive modernisation scheme brought a new Thomas converter melt shop an open hearth shop,a blooming mill and the heavy section mill, called rolling mill NO1, that is partly still in use today.

In 1926 the Union works became part of the Vereinigte Stahlwerke AG from Düsseldorf.

After this company was dismantled after the second world war the Union works joined the Hörder Verein , another steel company from Dortmund, to form the Dortmund Hörder Hüttenunion (DHHU).

In 1957 a continuous medium section rolling mill was erected now called rolling mill NO 2.

In November 1963 the last of the five Union blast furnaces and the Thomas converter steel mill were closed for good.

In 1966 the DHHU was taken over by the Hoesch Stahl AG from Dortmund. The division was called “Werk Union” from now on.

In 1981 the open hearth shop and the rolling mill NO2 were closed.

In 1992 Hoesch was bought by the Krupp company from Essen. Two years later the new subdivision Hoesch Spundwand und Profile was founded.

From 1999 on the remaining rolling mill was part of the ThyssenKrupp Stahl company to be sold to the Salzgitter Stahl company in 2000.

HSP is the only producer of sheet piles and heavy sections in Germany now.

Further images.

1. Heavy sections mill

2. Blooming mill

3. Former Thomas steel mill

4. Open hearth shop

5. Roll lathe plant

6. Forge

7. Medium sections mill

8. Boiler house

9. Repair shops

Vintage coke ovens dismantled

During today’s visit at ArcelorMittal’s Zdzieszowice coke plant in Poland I could convince myself that Europe’s probably oldest existing coke oven batteries are completly dismantled by now.

The batteries NO 1 & 2 were built by Gräflich Schaffgotsche Werke in 1932 and 1938.

The location 50 kilometers away from the next coal mine and without any steel industry in the vicinity was chosen mostly for political reasons. The administration had decided to offer industrial jobs for the German population in this rural part of Silesia.

The design for this new coking plant was done by Fritz Schupp and Martin Kremmer from Germany. Both batteries had a stamp charging system and were built by the Still company. The batteries were shut down in 2008 and dismantled in 2010.

ArcelorMittal Zdzieszowice today runs 8 oven batteries (3-6 are stamp charged and 7,8,11 and 12 are top charged) of which 4 were rebuilt in the last 10 years. Batteries NO 9 and 10 were dismantled recently too.

Zdzieszowice is the largest coke plant in Europe producing more than 4 mio. tons of metallurgical and domestic coke each year.

Steelton rail rolling mill

The Steelton plant was founded in 1867 by the Pennsylvania Steel Corp.. It was the first mill in the U.S. built exclusivly for the production of steel.Main product were steel rails already.

Three blast furnaces and a Bessemer mill were erected along the Susquehanna river in the late 19th century

In 1917 the mill was taken over by Charles Schwab’s Bethlehem Steel Corp.

The blast furnaces were closed for good in 1960.Steel was produced now by remelting scrap in open hearth furnaces only.

The open hearth furnaces were replaced by electric arc furnaces in 1968.A continuous caster was installed in 1983.

In 2001 the Bethlehem Steel Corporation went bankrupt and was taken over by ISG which later became part of ArcelorMittal.

Today ArcelorMittal operates a 150 ton electric arc furnace, a continuous bloom caster, a 44” blooming mill, a 20” bar mill, and the 38-25” rail mill at Steelton. Large scale ingot teeming is still done also.

Steelton is one of only three remaining rail producers in U.S. today.

Dortmunder Union Brückenbau

Once one of the largest engineering companies in Europe (later Rheinstahl Union Brückenbau AG) whose steel bridges are still present everywhere in Germany and that built the Assuan dam in Egypt has nearly disappeared by now.

The workshop south of the Dortmund harbor was famous for it’s 276 meter long and 60 meter wide main hall that housed a bridge assembly line.

This famous structure built in 1898 was torn down in 1995.