The Huta Kroleweska in Chorzow, Poland was founded in 1797 and started the production of pig iron in 1802. It was named “Königshütte” in honour of the Prussian King.

In 1843 a puddling steel mill and the first rail mill went into production.

Until 1860 four blast furnaces and a coke plant were built.

In 1872 the German painter Adolph Menzel visited the works to create his famous painting “Eisenwalzwerk (moderne Cyclopen)”

An open hearth melt shop was installed in 1880 and a Bessemer plant was added in 1895. By 1909 the Puddling and Bessemer mills were closed and in 1912 a Thomas converter melt shop was comissioned.

Under Polish administration the plant was renamed “Huta Pilsudski” in 1935. During the German occupation the mill was called Königshütte again and after the war the name of “Huta Kosciuszko” was used.

In 1949 the DEMAG medium and light sections rolling mill was installed.

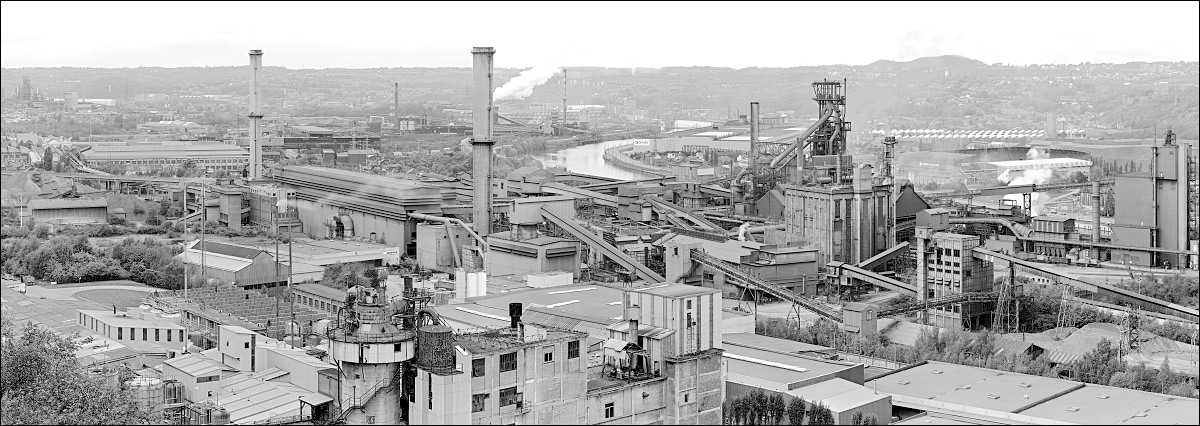

In the 1950ies new blast furnaces and coke oven batteries were built.

More than 8000 people were employed.

Steel production ceased in 1978, the coke plant was closed in 1982 and the last blast furnace was blown out in 1991. In 1992 the wire rolling mill was closed down.

In 1994 a new walking beam furnace was installed for the heavy sections rolling mill.

In 1997 the light and medium sections mill was modernized.

The Huta Kosciuszko became a shareholders company in 1998.

In 2007 the ArcelorMittal steel company takes over the mill under the name “Huta Krolewska” (Germ., Königshütte).

Huta Krolewska today runs a heavy sections rolling mill mostly for rails and a light and medium sections mill.

Raw materials are provided by the Huta Katowice in Dabrowa Gornica.

Further images at stahlseite.de.

Video done by a french film maker in the 1980ies.