The iron foundry Zeitzer Guss runs one of the largest induction furnaces in Germany. Founded in 2007 it is the latest foundry in Germany. It was built on ground of the much older ZEMAG (Zeitzer Eisengießerei und Maschinenbau AG) plant from 1855. Zeitzer Guss produces hand formed castings up to 30 tons a piece.

Further images at Stahlseite.

Big Cupola II

The Fritz Winter iron foundry in Stadtallendorf, Germany operates one of the largest foundry melt shops worldwide. Two hot blast cupola furnaces and ten induction furnaces can melt up to 2800 tons of iron each day.

The company was founded in 1951 on ground of a former explosives factory.

Today the plant is the largest independent foundry in Europe employing 3500 people.

Main product are engine blocks and brake discs for the car industry.

Further images at Stahlseite.

Demolition Started

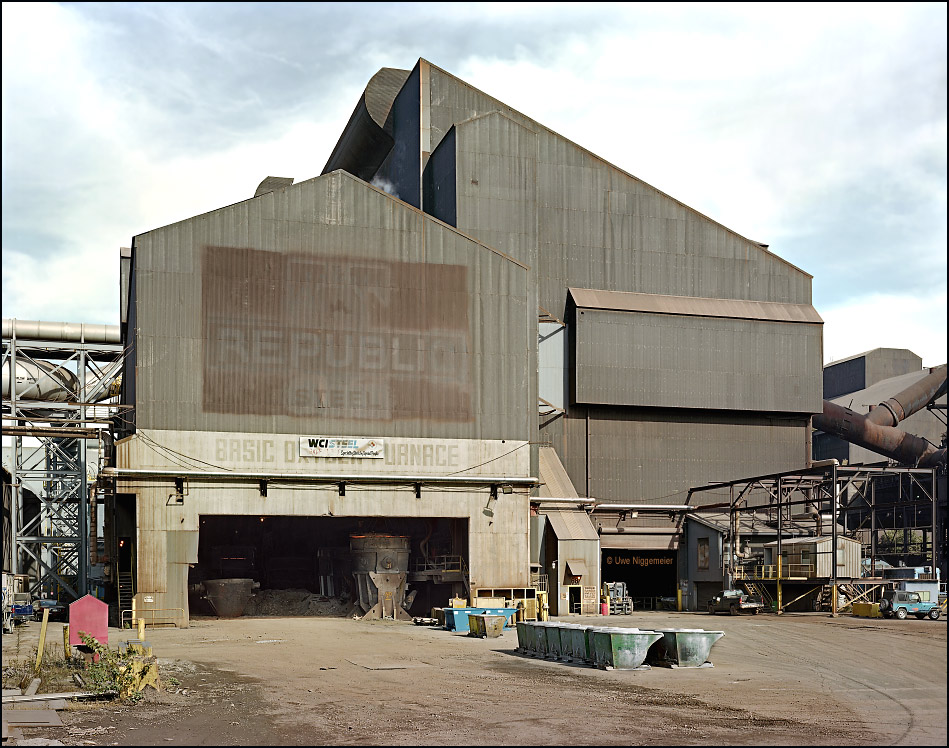

Demolition started at the former RG Steel plant in Warren,OH that was purchased by the Hilco company in May. This deal required to market the hot mill for three months before beginning to raze the plant. Those three months expired at the end of August.

Founded in 1912 as the Trumbull Steel Co., the mill has a long history in steel production. In 1928, the company merged with Republic Iron and Steel Co. and, two years later, was renamed Republic Steel Corp. Another merger changed its name to LTV Steel Co. when it combined with J&L Steel Corp. in 1984. The company became Warren Consolidated Industries, Inc. in 1988.

WCI Steel employed 2,600 people, and had an annual steel capacity of 1.5 million tons. In 2008 WCI was taken over by the Russian steel company Severstal.

Three years later Severstal sold the plant to RG Steel who filed bancruptcy in 2012.

The Warren Blast Furnace once was the largest worldwide.

A few images from 2007.

ArcelorMittal Closes It’s Last Open Hearth Furnace

AM Krivoy Rog, Ukraine announced to close it’s last open hearth furnace as soon as the modernization of BOF vessel No. 5 is finished. This will probably happen in late 2014.

The 700 ton tandem open hearth furnace No. 6 is the last of it’s kind at ArcelorMittal, the worlds’s largest steel producer.

Further images.

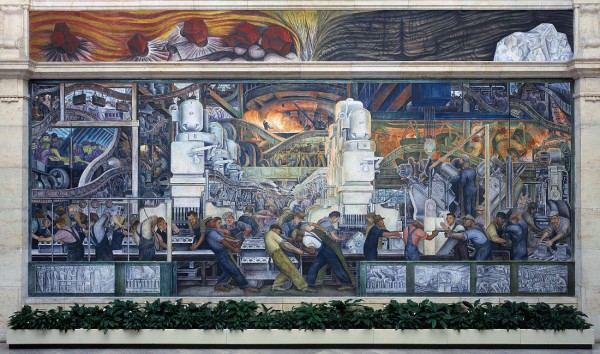

Detroit Murals

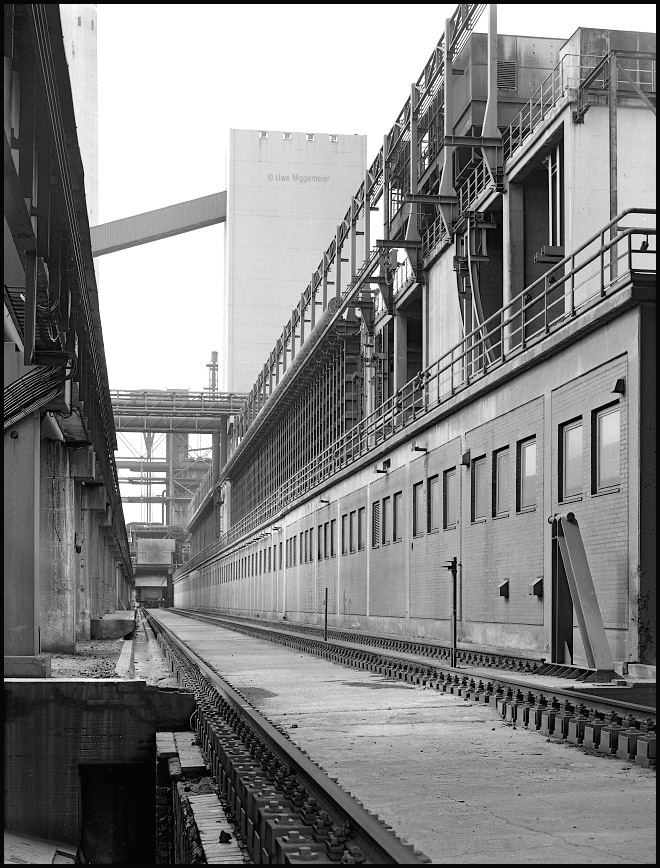

Kokerei Kaiserstuhl

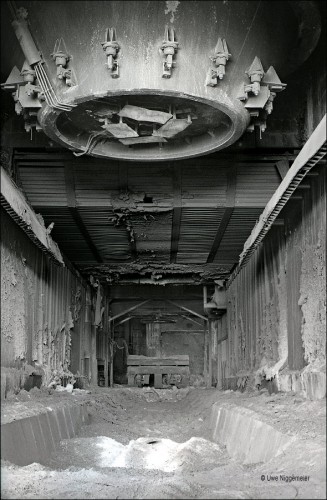

These days the last remains (coking coal tower, dry quenching facilities) of the coking plant Kaiserstuhl in Dortmund, Germany are knocked down.

The plant was built in 1992 to be the most modern coke making facility in Europe.

It supplied coke to the nearby Hoesch blast furnaces. The plant inluded two coke oven batteries of 60 furnaces each, and both a dry and a wet quenching facility.

When ThyssenKrupp announced the closure of it’s (former Hoesch) blast furnaces Kaiserstuhl was shut down after being in operation for just eigth years .

Ten years ago most of the mill was dismantled and rebuilt in the Shandong province, China.

This relocation was documented in the exiting movie Losers And Winners.

Further images of this plant at Stahlseite.

Vintage Image #9

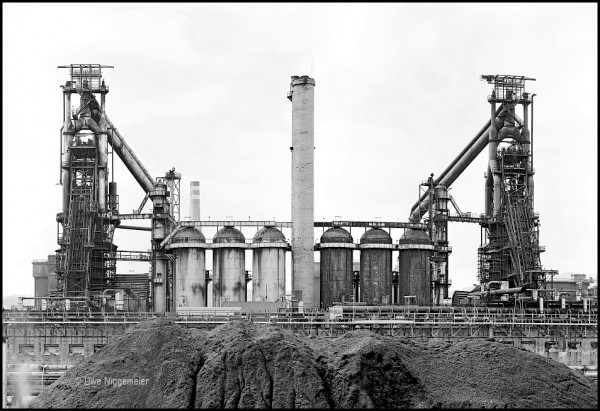

Blast furnaces Carmen (named after Carmen Polo, Franco’s wife), Joaquina, Rosario and Carmen IV in Aviles, Spain. Later called blast furnaces 1-4.

The furnaces were built in between 1957 and 1969 by the public enterprise ENSIDESA (Empresa Nacional Siderúrgica Sociedad Anónima). Hearth diameter was 8,69-8,99 meter.

Furnace 1&2 were shut down in1989 and furnaces 3&4 in the mid 1990ies after the hot metal production was translocated to the newer furnaces in Gijon.

By 2001 all furnaces were dismantled.

Last Open Hearth Built In West Germany ?

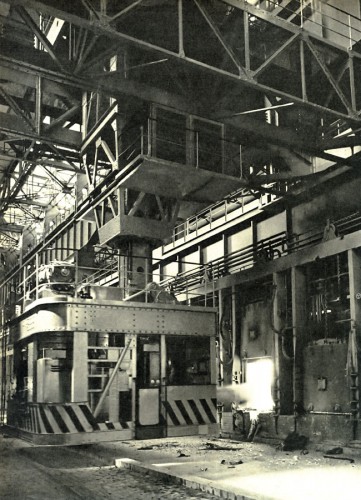

In between 1954 and 1962 the Hoesch company in Dortmund, Germany built it’s third open hearth melt shop (SM-Stahlwerk III).

Two 180 ton furnaces were installed by 1956, two DEMAG 210 ton furnaces were added in 1961 and 1962. These might have been the last to be commissioned in West Germany.

Monthly output was less than 100000 tons, not enough to compete with the new BOF shop in Dortmund Hörde built in 1963 producing more than 300000 t/m.

The open hearth shop 3 was closed in 1982.

Some images of it’s remains: Stahlseite.

The Last Furnace In Town

My hometown Hagen once was one of the major steel producing communities in Germany.

Blast furnaces,open hearth shops and numerous foundries shaped the confined townscape in the narrow valleys of the Volme and Ennepe rivers.

The largest steel mill, the Hasper Hütte owned by the Klöckner company, was closed in 1972 and the huge Wittmann steel foundry next to it just one year later.

The last major steel producer in town, the open hearth shop of Stahlwerke Südwestfalen was shut down in 1976, smaller ones like the Remy speciality steel mill followed in the 1990ies.

The Eisenwerk Geweke was founded in 1910 and is specialized in steel fittings.

A five ton electric arc furnace and a small induction furnace are producing castings up to four tons a piece.

Further viewing at Stahlseite.