is the last rail mill in France.

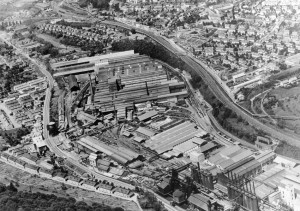

The former Usine Saint Jacques in Hayange, France was founded by the De Wendel family in 1892. After the closure of the iron and steel production in 1972 the rail mill was outsourced by USINOR (successor of the De Wendel group) in 1994 now called Sogerail and owned by Unimetal.

In 1999 the mill was sold to the British Steel company from the UK to become part of the new Corus Group the same year.

Since 2007 the rail mill in Hayange is called Tata Steel Rail and part of the Indian Tata group.

Rails up to 108 meters in length can be produced. Billets for the rolling mill come from Tata’s steel plant in Scunthorpe, England.

Further viewing.

Vintage Image #11

The Last German Rail

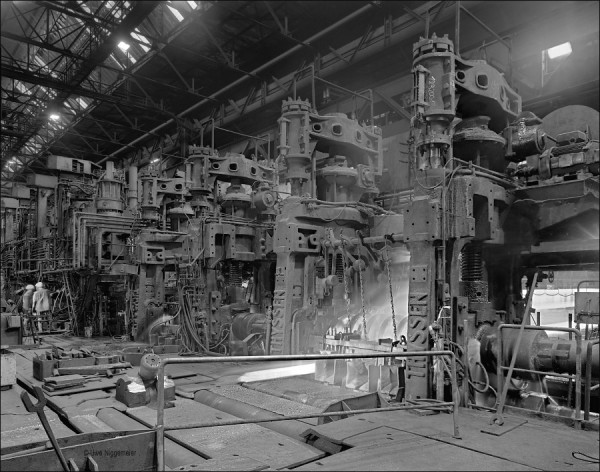

was rolled yesterday at the TSTG rail mill in Duisburg.

The rolling mill exists since 1894 built by the August Thyssen Hütte and sold to the Austrian Voest Alpine group in 2001.

Voest is still producing rails at it’s Donawitz works in Austria.

TSTG’s finishing stands were built in 1924 named “Fertigstrasse 1” back then.

Some images.

Final Verdict

U.S. Steel announced the permanent closure of it’s Hamilton, Canada based iron and steel making facilities.

The former Steel Company of Canada (STELCO), founded in 1910, once employed more than 14000 people on the banks of the Lake Ontario.

The plant was bought by U.S. Steel in 2007 and partly idled in 2010.

Only some hot rolling and coke making activities will be continued.

Further images at Stahlseite.

Rolling Mill Operators

Big Cupola IV

This is the old Carlshütte in Limburg, Germany, better known as Buderus Eisenwerke for more than a century.

The company was founded in 1900 by Carl Schlenck from Nürnberg.

In 1907 the Buderus company took the mill over to produce sewer and drainage castings.

Four cupola furnaces were installed. During world war II. a converter for steel castings was in use.

During the 1950ies and 60ies more than 1200 people were employed.

In 1979 a new hot blast cupola furnace was built.

In 2009 the former Buderus Kanalguss was bought by the MeierGuss group.

Further images.

Vintage Image #10

The blast furnaces of S.A. Métallurgique et Minière de Rodange-Athus (MMRA) in Rodange, Luxemburg and the the ropeway that connected them to the iron ore mine Doihl.

Both were closed in 1978. Two rolling mills still exist here.

From Iron To Steel

The iron foundry Eisenwerk Hasenclever was built on ground of the old Auhammer forge in Battenberg, Germany in 1913. Cast iron crankshafts become the main product.

In 2011 the old cupola furnace was replaced by 6 induction furnaces to produce high temperature resistant steel castings.

More images at Stahlseite.

Big Cupola III

Though not as large as the Fritz Winter furnaces this hot blast cupola still churns out more than 30 tons of cast iron each hour.

Heinrich Meier Eisengiesserei in Rahden, Germany was built in 1960.

In 1987 the new cupola furnace was installed by the Küttner company from Essen.

Main products are manhole covers and drainage systems.

Further viewing.

Another Survivor

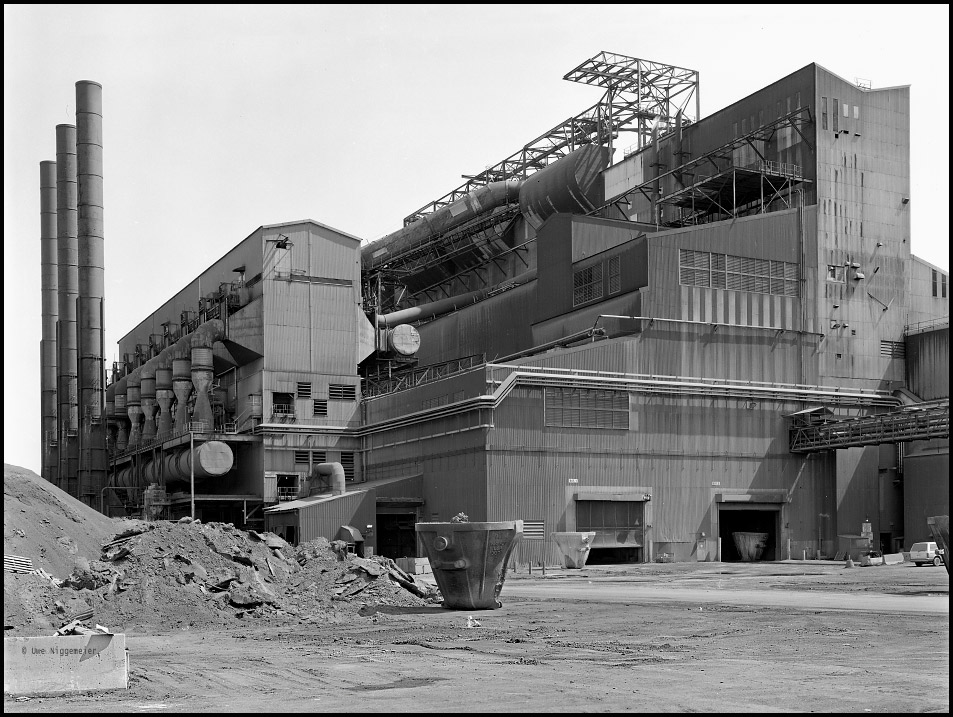

ESW Röhrenwerke in Eschweiler close to Aachen, Germany is the last survivor of the once huge Eschweiler Bergwerksverein (EBV) combine of coal mines and steel plants and it runs the only planetary tube rolling mill in Europe.

Further images.

The tube mill was founded in 1914 by the Eschweiler- Ratinger Maschinenbauaktiengesellschaft (ERMAG). In 1917 an open hearth shop was added to ensure the steel supply. In 1924 the plant was taken over by the Eschweiler Bergwerksverein (EBV), a mining company mostly owned by ARBED from Luxemburg. Pig iron was now supplied by the nearby EBV blast furnaces (Concordiahütte). In 1957 a new electric arc melt shop was built on ground of the now dismantled blast furnace site. In 1964 a continuous caster was added.

An new innovative planetary tube rolling mill (PSW) gradually replaced the outdated pilger rolling mills in 1976.

In 1984 the site was sold to the Maxhütte steel company from Bavaria. The EAF melt shop closed in 1986 and one year later the Maxhütte went bancrupt. In order to save the new tube rolling mill the former plant manager, among others, took the mill over in 1987.ESW Röhrenwerke produces seamless steel tubes for the oil and gas industry, boilers and engineering.