in Sluiskil, Netherlands was closed 20 years ago in September 1999.

The coking plant produced metallurgical coke for blast furnaces in the Saar region, France, and Ghent and Clabecq in Belgium.

Category Archives: Other

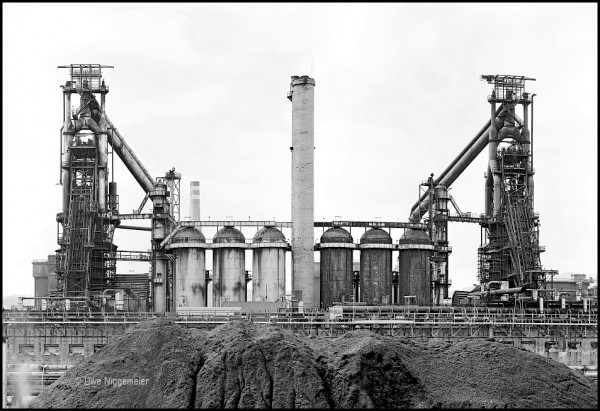

Blast Furnace 12

Store Steel

The steel works in Store, Slovenia were founded in 1851.In 1875 the mill became part of the Berg- und Hüttenwerk Store and mostly produced casted and forged materials.In 1912 an open hearth steel making shop was installed. In the early 1970ies a new steel mill (60 ton electric arc furnace) and a bar rolling mill where built nearby called Store II. In 1978 open hearth steel making was closed down. In the 1990ies the company was privatized and got it’s new name Store Steel in 2003.

Main product are steel bars for the automotive industry.

Images on my website now.

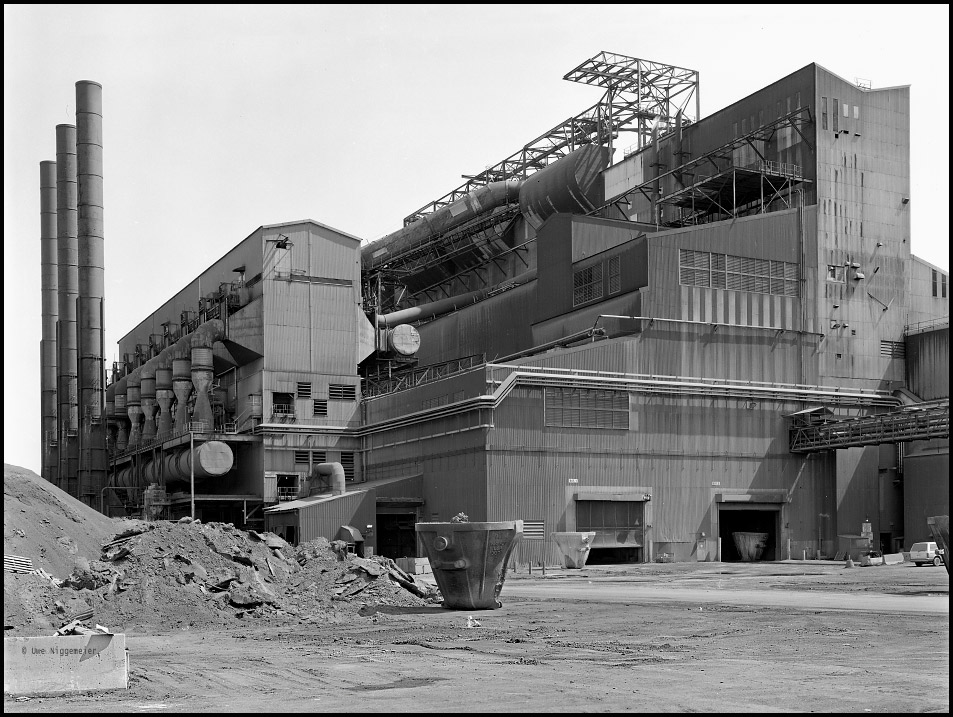

DMKD, Ukraine

The steel plant in Dneprodzerzhinsk was founded in 1887 on the banks of Ukraine’s largest river the

Dnepr supplied with coal from the Donezk bassin and iron ore from Krivoy Rog. The mill was nationalized in 1917 and named after Feliks Dzierżyński (Revolutionary and founder of the Sowjet secret police) in 1925.

Today the plant is privatized and runs four blast furnaces (No. 1/8/9/12) a BOF shop including two 250 ton top blown vessels. Two continuous casters and several rolling mills for railroad axles, rails, billets, tube blanks, medium sections and sheet pile.

Images now at Stahlseite.

Stahl Gerlafingen

The old Von Roll site in Gerlafingen is the only carbon steel producer in Switzerland (the only other steel mill is Swiss Steel, producing speciality steels). Images now at Stahlseite.

The steel mill in Gerlafingen was founded in 1818 by Ludwig von Roll & Cie one of the oldest industrial enterprises in Switzerland. The company changed it’s name in 1823 and was now called Ludwig von Roll’sche Eisenwerke, a name they kept until the early 1960ies.The first Swiss rolling mill was installed in Gerlafingen in 1836 the second followed ten years later. Iron was produced from local ore deposits in a blast furnace in nearby Choindez.

Most raw materials for the rolling mill in Gerlafingen came from abroad though. After this supply become increasingly difficult during the first world war an open hearth melt shop was installed in 1918 and closed down in 1921. Steel was produced from now on in electric arc furnaces only. The top charging system for EAFs, now a worldwide standard, was invented here in the 1920ies.

From 1962 on the company called itself Von Roll AG.

After years of financial trouble the Von Roll AG sold it’s steel making branch to it’s competitor the Von Moss AG to form the new Swiss Steel company.

Swiss Steel was taken over by Schmolz & Bickenbach from Germany in 2003. S&B sold the Gerlafingen works to the Italian Beltrame group in 2006 to focus it’s activities on speciality steel making. Stahl Gerlafingen today runs a 70 ton electric arc furnace with a scrap preheating shaft, a continuous caster and two rolling mills (rod and wire). Main products are reinforced and structural steels.

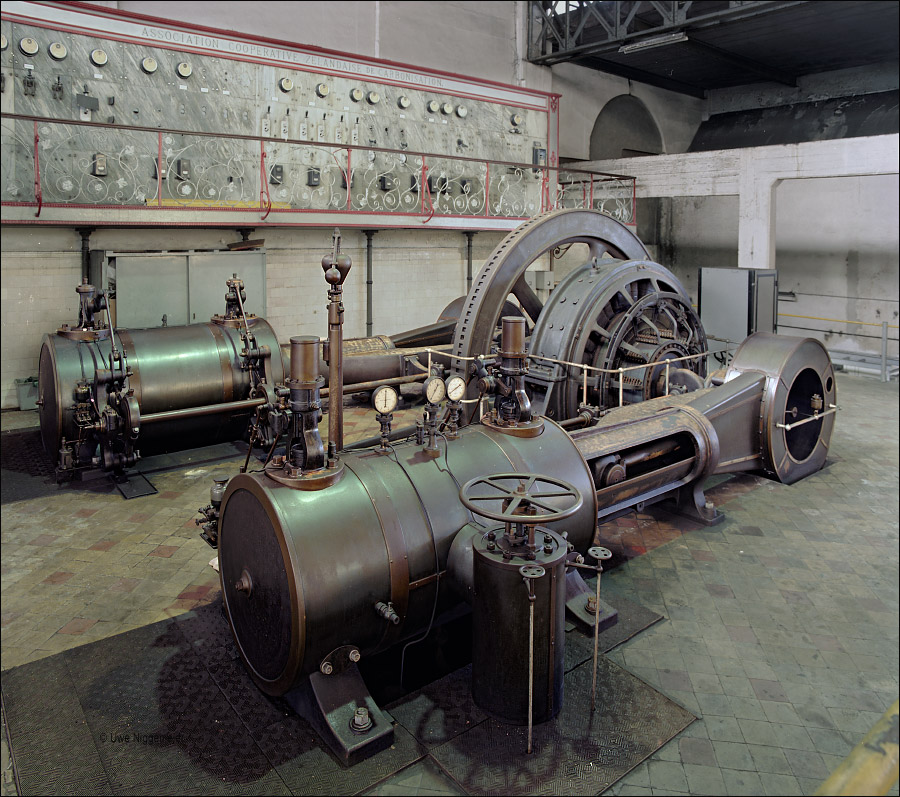

Vintage Image #11

Final Verdict

U.S. Steel announced the permanent closure of it’s Hamilton, Canada based iron and steel making facilities.

The former Steel Company of Canada (STELCO), founded in 1910, once employed more than 14000 people on the banks of the Lake Ontario.

The plant was bought by U.S. Steel in 2007 and partly idled in 2010.

Only some hot rolling and coke making activities will be continued.

Further images at Stahlseite.

ArcelorMittal Closes It’s Last Open Hearth Furnace

AM Krivoy Rog, Ukraine announced to close it’s last open hearth furnace as soon as the modernization of BOF vessel No. 5 is finished. This will probably happen in late 2014.

The 700 ton tandem open hearth furnace No. 6 is the last of it’s kind at ArcelorMittal, the worlds’s largest steel producer.

Further images.

Vintage Image #9

Blast furnaces Carmen (named after Carmen Polo, Franco’s wife), Joaquina, Rosario and Carmen IV in Aviles, Spain. Later called blast furnaces 1-4.

The furnaces were built in between 1957 and 1969 by the public enterprise ENSIDESA (Empresa Nacional Siderúrgica Sociedad Anónima). Hearth diameter was 8,69-8,99 meter.

Furnace 1&2 were shut down in1989 and furnaces 3&4 in the mid 1990ies after the hot metal production was translocated to the newer furnaces in Gijon.

By 2001 all furnaces were dismantled.

Nizhny Tagil Region

The Ural region is a cradle of the Russian iron and steel industry.

Based on it’s rich iron ore deposits a vast number of charcoal fired blast furnace sites emerged in the 18th century. Most of these are gone today, replaced by the huge combines of the communist era. A few have survived, mostly rusting away in the harsh climate of the eastern Ural:

The Verhnesinyachihinsky Metallurgical Plant in Werchnjaja Sinjatschicha was founded 1769 and went bancrupt in 2012.

The Alapaevsk Iron Works origin from 1704 and seem to be idled by now.

The Kuibyshev Metallurgical Plant in Nizhny Tagil goes back to the Demidov iron company from 1725 and was closed in 1987. It hosts a museum but seems to be in a rather poor condition and seldom opened to the public.

Images at Stahlseite.de .