und Verpuppenstubung von Industrieanlagen schreitet auch in China erfolgreich voran.

Funktionale Zusammenhänge spielen, wie bei uns, beim Erhalt nur eine sekundäre Rolle. Und so wandert der letzte Antikhochofen mal eben auf den Parkplatz vors Werkstor.

Rolltreppen dürfen natürlich auch nicht fehlen.

Category Archives: Other

Can anyone raise the bid ?

16, according to my estimation this is the largest number of blast furnaces in a steel plant that currently exists. And that probably applies to the past as well.

US Steel’s Gary works in it’s heydays never had more than 12, Sparrows Point 10. Reichswerke in Salzgitter, Germany had 32 planned but only 12 were completed.

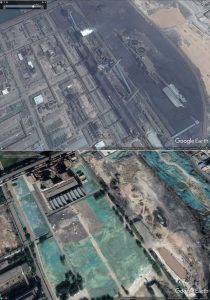

Rizhao Steel in China (Shandong Province) was founded in 2003. After only 181 days of construction, the first blast furnace was blown in September 2003. By 2008, 15 additional furnaces had been built (cap 7.5 mio t/y).

The small size of the blast furnaces (2 x 450 m³, 2 x 530 m³, 2 x 580 m³, 10 x 1080 m³) is striking. This would have made the plant uncompetitive in Western Europe and especially in North America already in the 1960s.

The installation of such small furnaces was widespread in China (presumably due to poor coke quality and a lack of know-how) until the economic crisis of 2008.

For economical and ecological reasons, however, the days of such blast furnaces are probably numbered in China as well.

Rizhao steel is building three new blast furnaces right now 3000 m³ volume each.

Three days over Shanxi

One of the few things I would really miss without internet are the aerial photos from various sources that can be used nowadays quite conveniently. Since 2009 (Vs. 5) Google Earth Pro offers the possibility to load historical aerial images. Although the quality of the images varies greatly and only recent history is covered, they are often very helpful. So I recently went on a flight over Shanxi, China’s largest coalfield. Shanxi, not to be confused with the adjoining Shaanxi province to the west, is about twice the size of Bavaria. Coal mining takes place in practically all parts of the province. From large open pits in the northwest to countless drift mines and deep mines.Despite the Corona winter I quickly buried the plan to mark all the mines I saw, because there are too many, and anyway it’s only mining, not my core business. So I focussed on coking plants. Shanxi is Chinas largest coke producer so I thought there must be some.

I found 260 on the aerial photos taken between 2008 and 2013 (there were s till five coking plants in Germany in 2008), and these are only the larger plants, the traditional beehive ovens, which must have still existed at that time, despite the ban, are barely visible on aerial photos.

till five coking plants in Germany in 2008), and these are only the larger plants, the traditional beehive ovens, which must have still existed at that time, despite the ban, are barely visible on aerial photos.

That China has made enormous efforts in the last 10 years to get its environmental problems under control which is evident from the fact that 146 of the approximately 260 coking plants that were still visible in Shanxi in 2008 have by now been shut down. With it’s remaining 114 plants (and I’m sure I’ve overlooked a few), Shanxi produces 20 % of China’s coke (2019), which in turn accounts for 60 % of the world’s production.

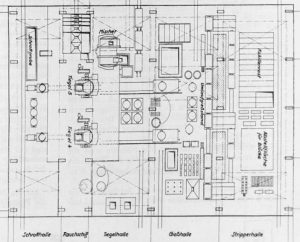

As in many communist economies, the core aggregates of the heavy industry are often standardized in China.

Very typical, for example, are stamp charged coking plants (relatively easy to recognize by the coal tower standing next  to the batteries) with two batteries and 4.3 meter furnaces. In these plants, even low-grade coals can be processed into usable blast furnace coke by precompression.

to the batteries) with two batteries and 4.3 meter furnaces. In these plants, even low-grade coals can be processed into usable blast furnace coke by precompression.

But there are ultra modern facilities too like the one in Xiangfen (65). The only coke plant I have ever seen with dust removal sheds on both the coke and pusher sides of the batteries

About half of the coking plants in Shanxi were top loaders (and apparently there were also combined plants) of older or newer design. 25 plants used non recovery ovens in which no by-products are produced.

Very few Chinese coking plants are attached to coal mines (as was common in Germany), some are operated by the larger steel mills, but by far the majority are stand-alone operations.

What is really remarkable is the fact that most of the coking plants do not have a rail connection. The entire supply and disposal of coal, coke and by-products at these plants is  handled by trucks.

handled by trucks.

If you are interested you can download the KMZ file for Google Earth with the coking plant locations in Shanxi here: Shanxi Coking Plants.KMZ

In case this program is not familiar: You can import the KMZ file directly (under File), the historical aerial photos can then be found under the 7th icon from the left in the menu bar (clock symbol).

Decommissioned coking plants have a red icon. Sometimes it was not quite clear whether the plant was already closed down, but if the pusher cars hadn’t changed position for years and the coal yard was empty I assumed that the place was dead.

Since most of the plants in Shanxi disappear quickly after they are shut down, the region is not very productive for the Urbex scene (is there one in China ?).However, some plants seem to be preserved (e.g. 212,211,128,136,194,235). Two stand apparently unfinished as malinvestments (251,252).

If you find any other coking plants please let me know, but beware those aerials can be a bit addictive.

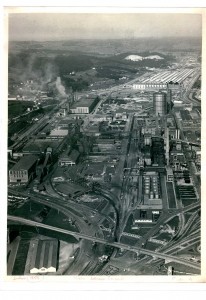

Die Stahlwerke der VÖEST in Linz

Zwischen dem 30.7.1973 und dem 21.12.1977 betrieben die Vereinigten Österreichischen Eisen- und Stahlwerke (VÖEST) in Linz als einziges Hüttenwerk in Europa drei LD-Stahlwerke parallel.

Das LD-Stahlwerk 1, das erste weltweit, ging im November 1952 mit zwei 30 t Konvertern in Betrieb und war an der Westseite an das existierende SM-Elektrostahlwerk angebaut worden. 1956 wurde dort ein dritter Konverter aufgestellt.

Im August 1959 nahm die VÖEST ihr zweites LD-Stahlwerk etwa 130 m nördlich des ersten in Betrieb. Hier arbeiteten die Tiegel 4 und 5 (50 t) 1968 wurde auch dort ein dritter Konverter installiert.

Im Juli 1973 ging schließlich das LD-Stahlwerk 3 in Produktion. Zunächst mit nur einem 140 t Konverter.

Jetzt betrieb die VÖEST in Linz drei LD-Stahlwerke, ein Siemens-Martin Stahlwerk (mit nur noch einem 200 t Ofen), ein Elektrostrahlwerk (mit zwei 20 t Öfen) und ein LD Versuchsstahlwerk mit einem 5 t Konverter (im SM-Stahlwerk).

1976 legte man dann den verbliebenen SM-Ofen und den Versuchskonverter still und im LD 3 wurde der 2. Konverter (Tiegel 8) angefahren.

Am 21.12.1977 endete die Produktion (mit nur noch einem Tiegel) im ältesten LD-Stahlwerk der Welt.

Im März 1988 erreichte das LD 3 seine endgültige Ausbaustufe mit der Inbetriebnahme des dritten Konverters (Tiegel 9, 140 t).

Das E-Stahlwerk legte man 1989 still und ein Jahr später endete die Produktion im LD 2.

Damit war im Grunde der heutige Zustand bei der Stahlerzeugung in Linz erreicht.

皇帝 椅子

© RVR, 1998, dl-de/by-2-0

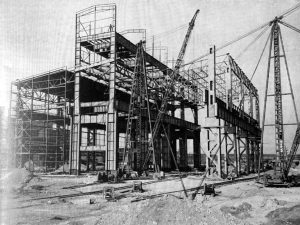

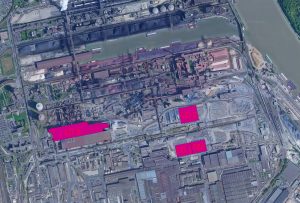

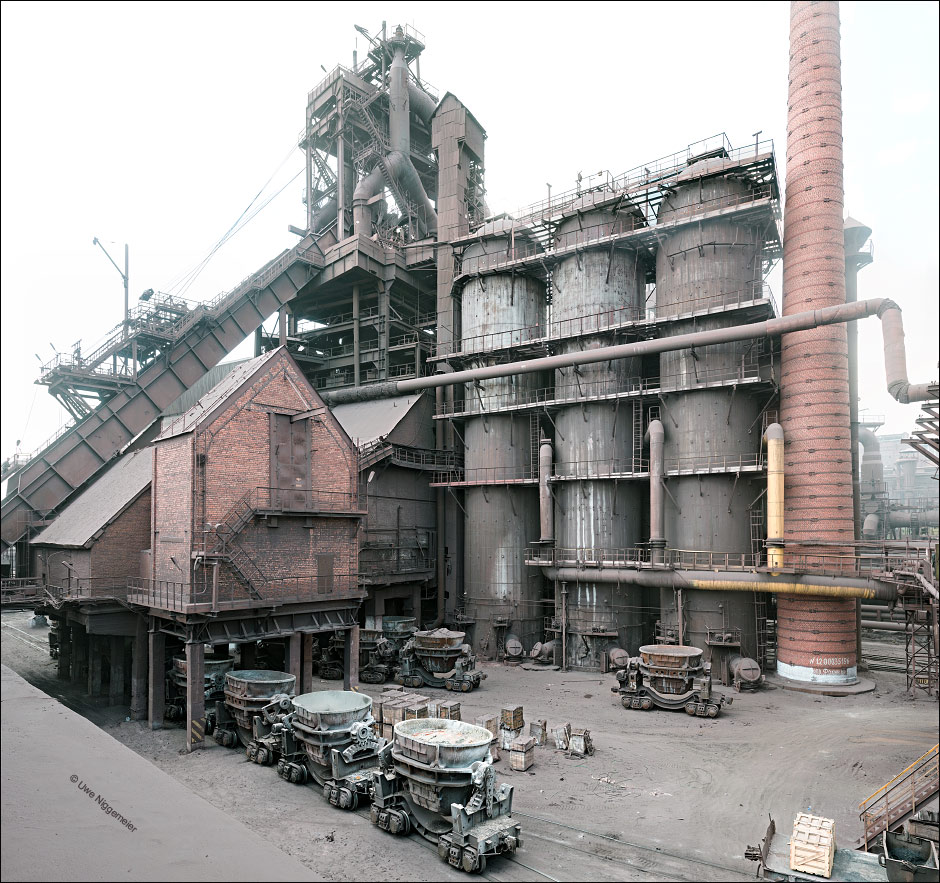

As is well known, the Kaiserstuhl coking plant in Dortmund, Germany was shut down 20 years ago, after only eight years of operation, and sold to China.

There, in the mining province of Shandong, the plant was rebuilt and put back into operation in 2006.

Rumor has it (e.g., Peter Liszio in “Der Kokshochofen”, 2015) that it was already shut down again in 2012 after major start-up problems.

That seemed a bit surprising to me. So I did a little research on this plant and indeed Kaiserstuhl still exists. The plant was even modernized again in 2019.

And as before, the coke dry cooling device is still more of a decorative nature.

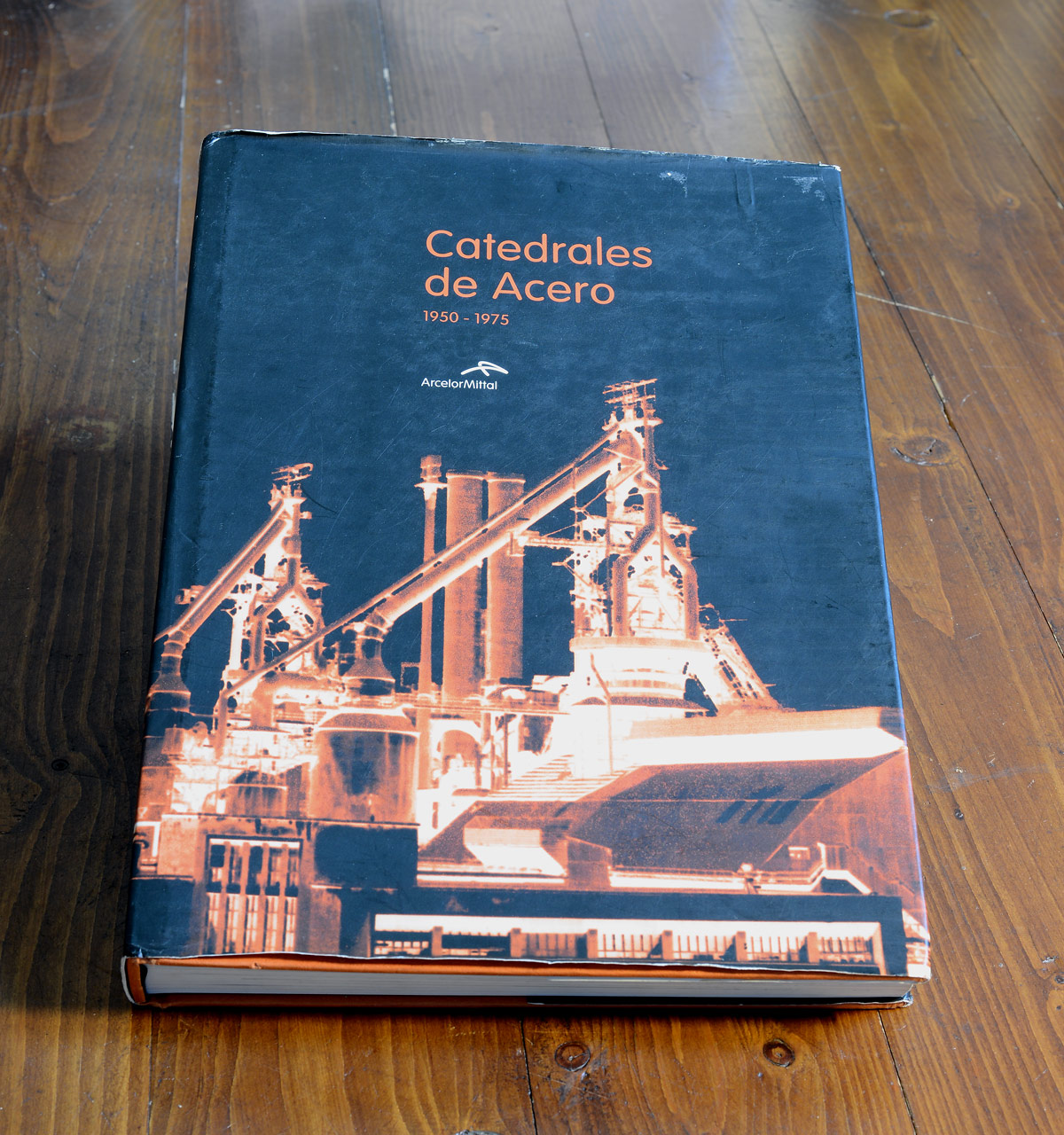

Catedrales de Acero

Obwohl schon 12 Jahre alt ist dieser 350 Seiten-Kracher eine echte Empfehlung zum Fest.

Die Geschichte der asturischen Stahlindustrie, und zwar nicht seit Adam und Eva sondern ab da wo es wirklich interessant wird, also ab 1950. Das ganze anhand von Fotografien die offenbar überwiegend auf Großformatnegativen entstanden sind.

Schwerpunkt sind die ENSIDESA in Aviles und die UNINSA in Verina. Aber auch die Werke in La Felguera, Mieres und Gijon werden berücksichtig.

Die Infos sind knapp aber hilfreich.

Eine ähnliche Publikation eines deutschen Stahlkonzerns ist mir nicht bekannt.

Voorwals

Blast Furnace No. 1

Steel Company of Canada

Aviles Coking Plant shut down.

Already on 30 September 2019, ArcelorMittal shut down the last two (3&4) of eight batteries at it’s Aviles coking plant in Spain.

The coking plant had been built from 1951 onwards as part of an economic programme; Franco’s dream of an industrialized Spain.

With it’s closure, the last major unit of the once state-owned steel group ENSIDESA will disappear.

The plant had 8 batteries of 30 ovens each and was planned and built by Didier-KOGAG-Hinselmann, an engineering company from Essen. It supplied coke to the finally four blast furnaces in Aviles (which have since been demolished).

In 1973, the state-owned ENSIDESA took over the neighbouring private steelworks UNINSA in Gijon. The coking plant there is also currently shut down, so that the last active blast furnace (furnace A) in Spain has to be supplied with imported coke. It is therefore questionable whether and when blast furnace B will be restarted.