The blast furnace Hamborn no. 4 at the ThyssenKrupp mill in Duisburg will be gone by next summer.

The furnace was built in 1964 replacing the old no. 4 that had been partly dismantled for reparation. It has a hearth diameter of 10,70 meters and a working volume of 2030m³.

The new furnace was the first one worldwide to be equipped with a bell less charging system. And it was the first in Germany to use coal powder injection.

Until May 2008, when the furnace was mothballed as a back up furnace it produced 43 mio. tons of iron.

Category Archives: Germany

Hoesch Phoenix Works, 1970ies

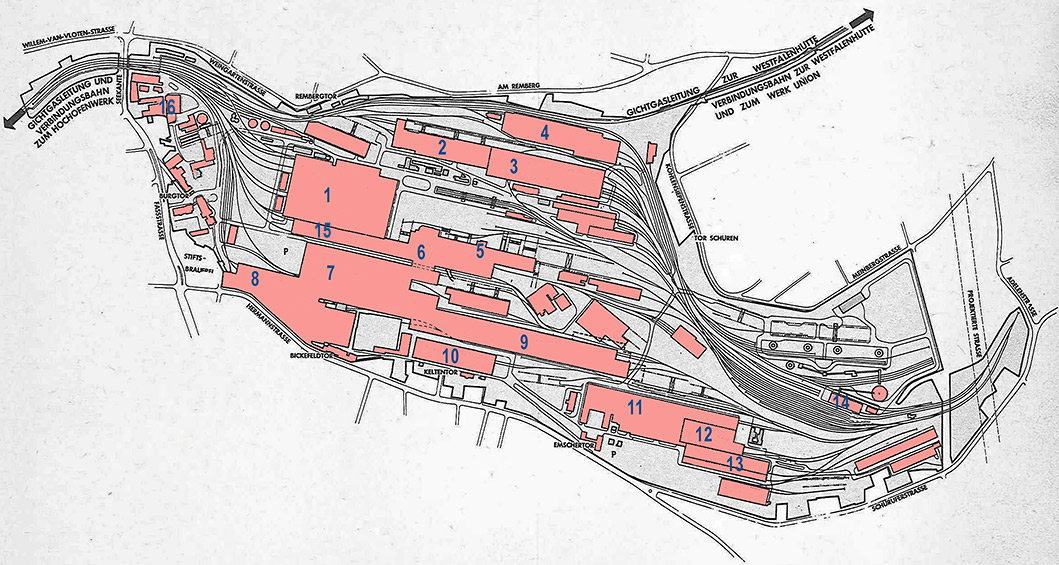

This plan shows the former Hermannshütte in Dortmund-Hörde, Germany, probably in the early 1970ies before the first continuous caster was built:

This plan shows the former Hermannshütte in Dortmund-Hörde, Germany, probably in the early 1970ies before the first continuous caster was built:

- BOF shop (Oxygenstahlwerk) closed 2001

- Open hearth shop IV ,former II (Siemens-Martin Stahlwerk IV, ehem. II) prob. closed in 1971

- Steel foundry (Stahlgiesserei) closed 1987

- Plate storage (Blechlagerhalle)

- Rolling mill 900 (900er Strasse)

- Blooming/slabbing mill (Blockbrammenstrasse) closed prob. 1985

- Heavy plate mill (Grobblechstrasse) closed 1982

- Finishing (Adjustage West)

- Finishing (Adjustage Ost)

- Roller lathe (Walzendreherei)

- Repair shop (Mechanische Werkstatt)

- Welding (Schweisserei)

- Forge (Pressbau)

- Slag mill (Schlackenmühle)

- Soaking pits (Tieföfen)

- Main storage (Zentrallager)

Today the area is transformed into a lake.

Some inside views.