The Republic Steel company just fired up it’s new electric arc furnace in Loraine, Ohio. It replaces two blast furnaces and a BOF steel making shop idled five years ago.

Blast furnace No. 3 has a hearth diameter of 8,68 meters, furnace No 4 is 8,83 meters wide.

The BOF shop was built in 1971 and it contains two 220 ton vessels.

Category Archives: Gallery

Zeitzer Guss

The iron foundry Zeitzer Guss runs one of the largest induction furnaces in Germany. Founded in 2007 it is the latest foundry in Germany. It was built on ground of the much older ZEMAG (Zeitzer Eisengießerei und Maschinenbau AG) plant from 1855. Zeitzer Guss produces hand formed castings up to 30 tons a piece.

Further images at Stahlseite.

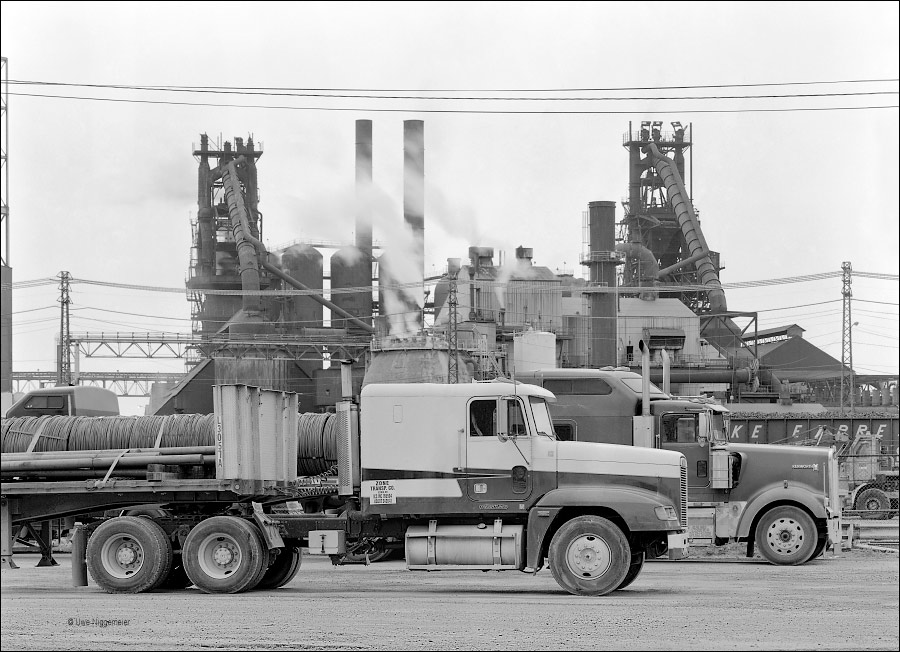

Burns Harbor: The last integrated steel mill built in the United States.

50 years ago the Bethlehem Steel Company from Pennsylvania started building a new, state of the art, integrated mill on the banks of the Lake Michigan. 3000 acres of land, neighbouring US Steel’s Gary works, were purchased and construction started in late 1962. Probably few could have imagined that Burns Harbor would be the last integrated mill in the U.S. to be built until today.

In 1964 the 160 “ plate mill was started followed in 1966 by the 80” hot strip mill. In between 1969 and 1972 two blast furnaces, a coke plant (164 coke ovens) and a steel mill, containing two 300 ton BOF vessels were started.In 1975 Bethlehem Steel’s first continuous slab caster started production. In 1978 a 110” plate mill and a third BOF vessel became operational.In 2000 the last ingots were poured.

After filing bankruptcy Bethlehem Steel was taken over by the International Steel Group (ISG) in 2003. Two years later Burns Harbor became part of Mittal Steel USA (ArcelorMittal since 2007).

Further images.

1: Blast furnace C

2: Blast Furnace D

3: Ore storage

4: Coal Storage

5: Coke plant

6: Sinter plant

7: BOF shop

8: Slab caster 1

9: Slab caster 2

10: 80″ hot strip mill

11: 160″ plate mill

12: 110″ plate mill

13: Cold rolling mill