Another German steel foundry had to close it’s gates.

After producing iron and steel castings for 120 years, Schütte Meyer & Co. in Iserlohn-Letmathe made it’s last pour in early April. Images here.

Author Archives: Uwe Niggemeier

Gienanth, Eisenberg

The Gienanth iron foundry in Eisenberg, Germany, founded in 1735, is one of the oldest working industrial enterprises in south-western Germany.

Today the foundry runs a 30t/h hot blast cupola furnace, installed in 1978, four induction furnaces and three 60 ton holding furnaces.

Major products are blocks for stationary and ship diesel engines.

Further images.

Liege Bassin Steel Industry, 1970

Saarschmiede, Völklingen.

Weirton BOF Shop Demolished

The former National Steel BOF shop was demolished last week.

The basic oxygen steel making shop with it’s 330 t vessels

operated from 1967 to 2005.

I visited it in 2004.

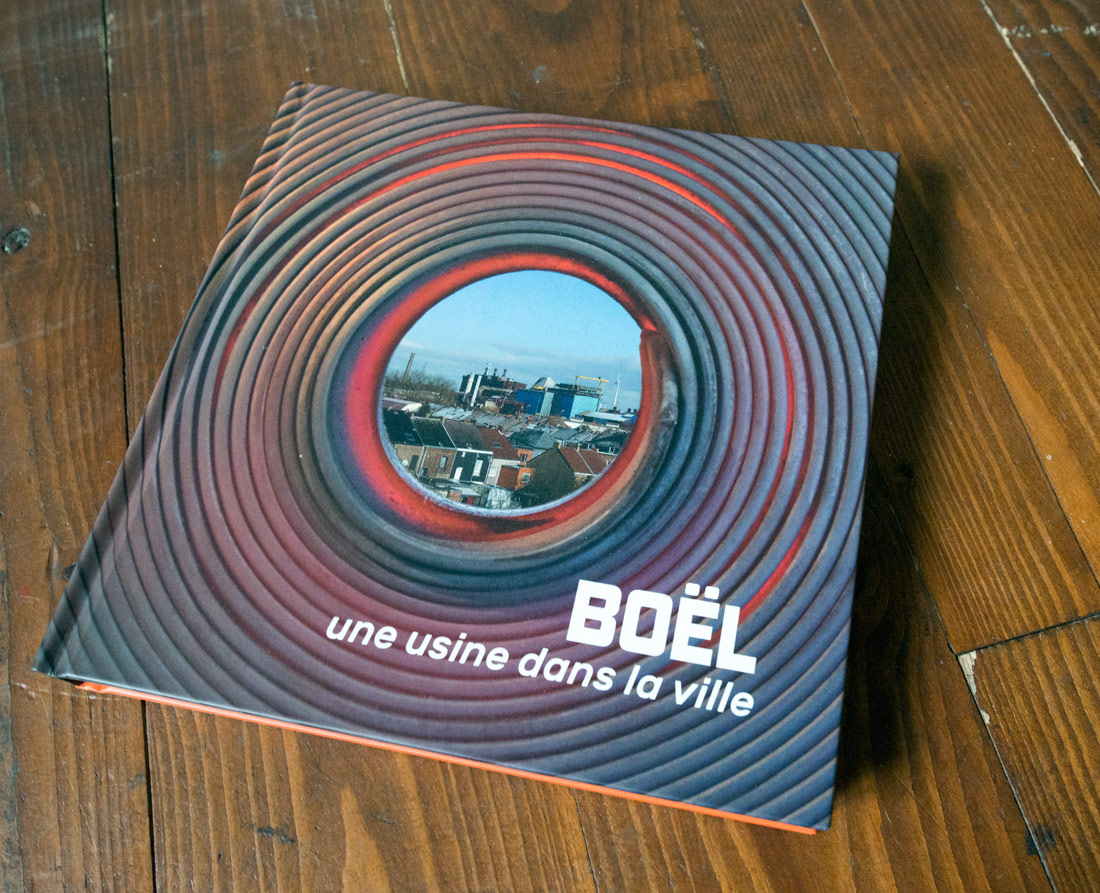

Usines Gustave Boel: New Book

VDM Metals, Unna

One of the lesser-known steel plants is VDM Metal’s melt shop in Unna, Germany.

It was built as a greenfield project in 1972. All smelting activities of Vereinigte Deutsche Metallwerke AG were concentrated there from then on.

In 1989, the Krupp Stahl AG took over VDM. The company became part of ThyssenKrupp in 1999.

Since 2015 VDM is owned by private equity firm Lindsay Goldberg from New York.

VDM Metals Unna operates a 30t, 15 MVA electric arc furnace, three 16t induction furnaces, a vacuum induction furnace and 3 electroslag remelting ovens.

VDM-Metals specialized in Nickel alloys and special alloyed steels.

Further images.

When the Marcinelle converters were blowing the banks of the Sambre were the place to be.

OBM-steel plant Marcinelle, Belgium, Feb.13th. 2019.

In 1973, after good results with the conversion of the old Thomas (basic Bessemer) plant at Monceau, Forges de Thy-Marcinelle et Monceau ordered a new OBM-steel making shop (Oxygen-Bodenblasen-Maxhütte) from a consortium VÖEST-Alpine–GHH-Sterkrade.The 17500 m² melt shop went into production in April,1976 and included a 2000 t hot metal mixer and three 150 t OBM-converters with 18 tuyeries each.

It was closed down in 2008 and will soon be gone.

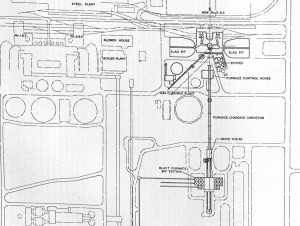

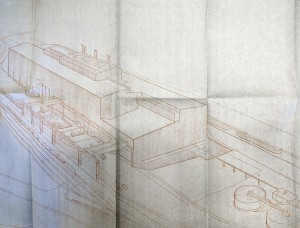

llanwern Blast Furnace No.3

One of the most short-lived fully integrated plants in the history of steel making was torn down 15 years ago.

Built by the Welsh steel maker Richard Thomas and Baldwins Ltd in 1962 the site became part of nationalised British Steel Corporation in 1967 and was called Llanwern works from then on.

In 1974 No. 3 blast furnace was the third to be built on the site and with it’s 11,2 m hearth and two tapping holes it was the first modern large volume furnace in Britain.

Furnaces No. 1 and No. 2 had a hearth diameter of 9,1 m.

Because of the lack of a deep-water iron ore unloading terminal the iron and steel making facilities, including the three 175 t converters of the BOF shop, where closed down in 2001 after producing steel for less than 39 years.